Factors that Impact the Plastic Injection Molding Parts Manufacturing

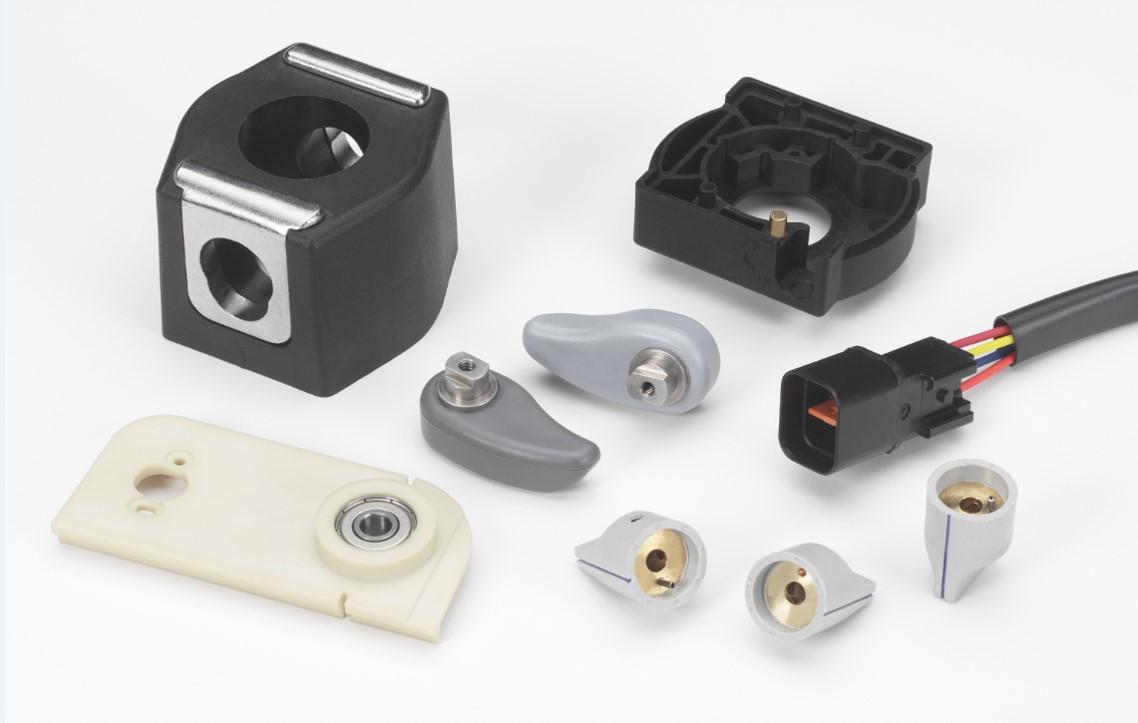

The key areas of focus in producing the complex and highly unusual perfect molding parts help the manufacturer to acquire them for several applications. For producing the perfect plastic injection molding parts, careful monitoring and designing are integral. This involves the inclusion and consideration of each step in a regular manner.

While purchasing the perfect injection molding parts, attention to certain details is necessary. These details hence help the purchaser for deciding long-term and stress-free management. some consideration is integral for the initiation of the process.

You May Also Read: Mold on Plastic: Different Mold Removing Instruments

However, others are important in the middle of acquiring the parts. However, the ultimate goal for this consideration is to make the customer happy.

Important considerations:

Several key considerations include:

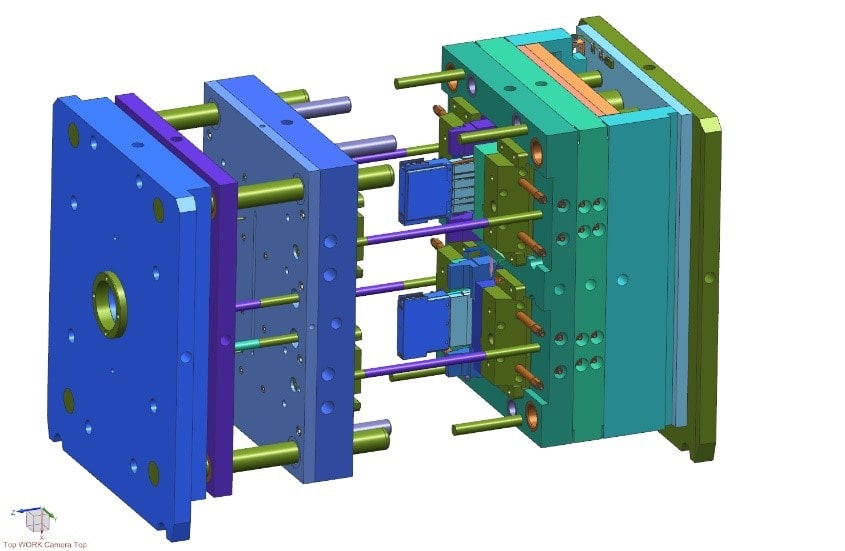

Mold Design

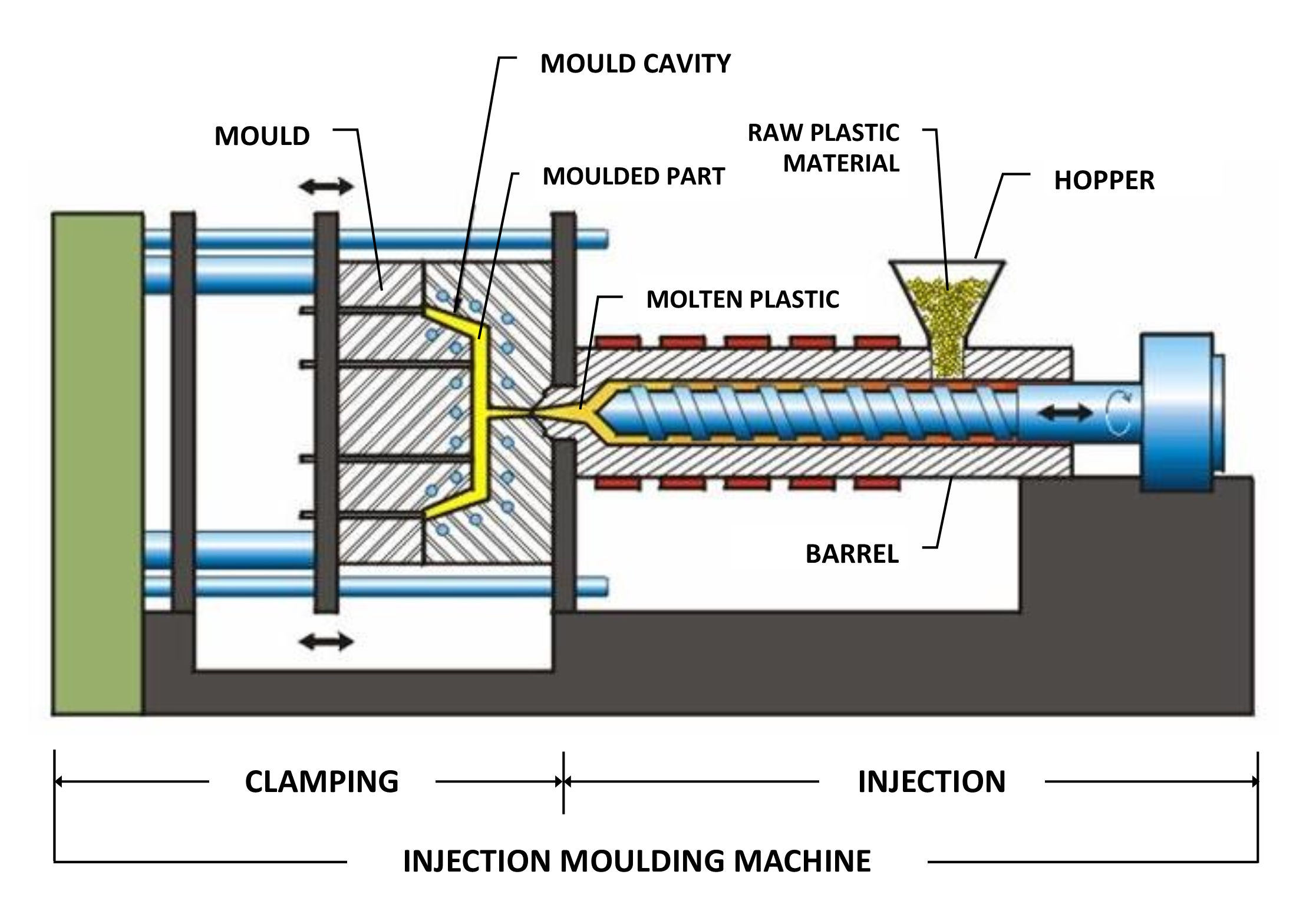

The foremost consideration in injection molding the design of plastic injection molding parts. This component is hence integral for the production of high-quality materials. The injection molding, therefore, ensures that a good mold must possess the production of a large number of parts. The high production of parts hence must follow efficiency and consistency.

The high-quality mold ensures the production of parts in a large number. This happens in producing the parts for the first time. This hence eliminates the chances of wastage of time and material as well. However, this requires experience in producing custom parts even in a challenging environment.

This includes the inclusion of state-of-the-art technology that works on using CAD and CAM software. Also, the perfect parts of producing companies consider a consultation with their customer. This is essential for the consideration of each part; its dimension and the quality of the material.

These elements hence ensure that the product must be rigid and hard enough to withstand certain elements. These include the external and internal environmental elements as temperature, pressure, and material.

The manufacturer hence makes sure that important considerations in the mold must be kept in mind. This thus ensures that the injection process works correctly. The consideration of molds includes the thickness of the mold walls. It also considers rib designs, the boss designs, the transition of the corner. Furthermore, these elements also take into account the welding lines of the injection molds. The placement of gates and vents also counts in acquiring the perfect plastic injection molding parts. These elements combine works well to obtain the ideal custom molded parts. After the creation of the mold design, there runs a DFM (design manufacturability analysis). This analysis thus ensures the mold design delivers the expected results.

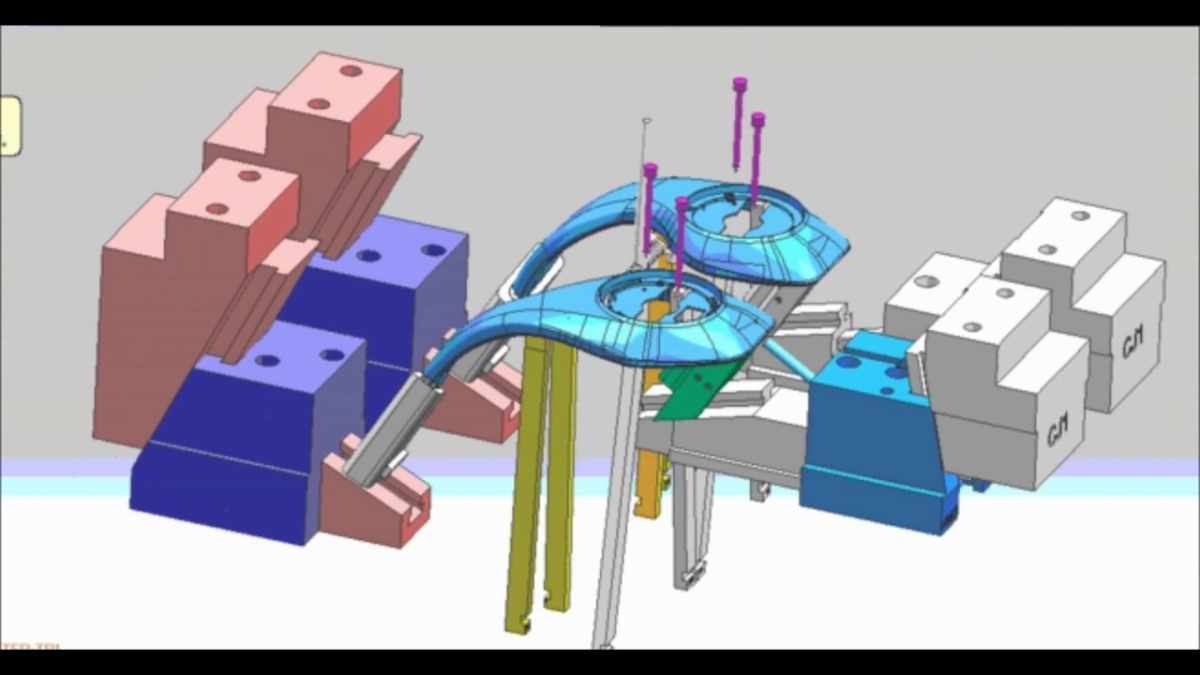

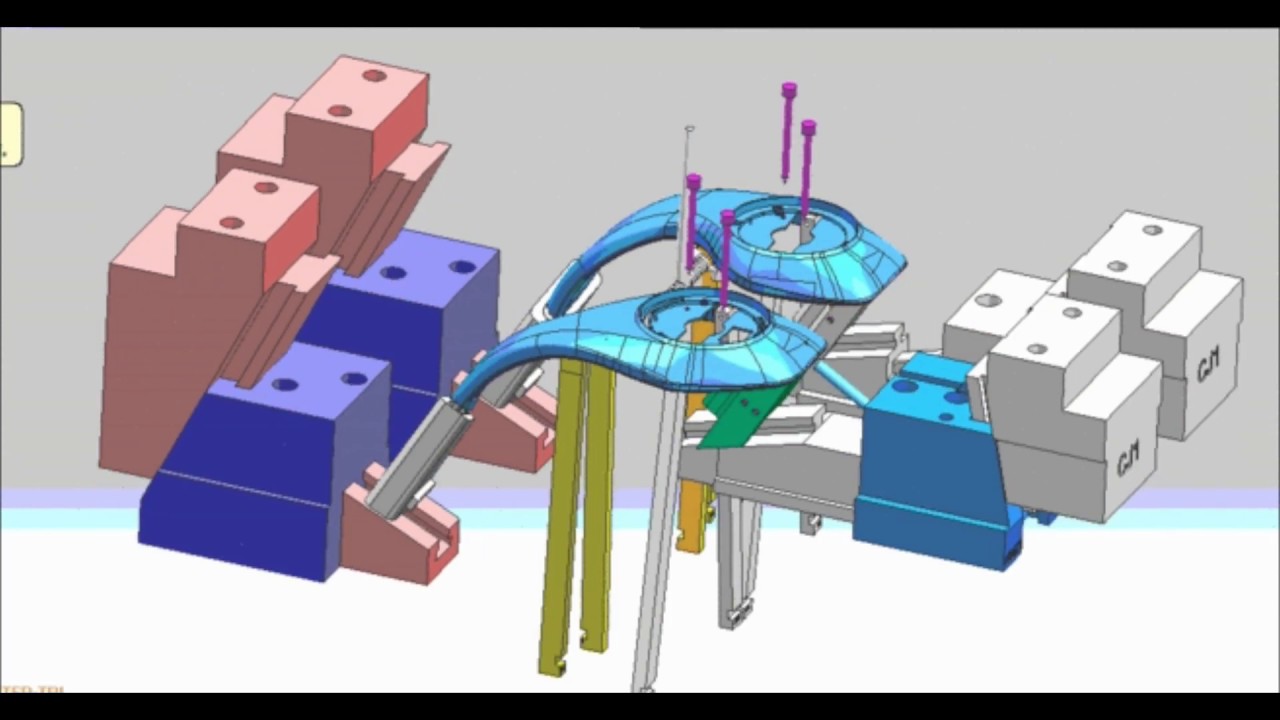

Designing Manufacturing Tools and Testing for Plastic Injection Molding Parts

For acquiring the perfect plastic injection molding parts, the presence of perfect mold is a compulsion. Without a perfect mold, there is no chance of getting the perfect part. This, therefore, requires the production of high-quality toolmaking consideration.

This step is important because the process of tool making is a time taking process. Therefore, by taking time, this must follow the optimum accuracy in production. This step hence is the most sustainable and substantial element in terms of investment for a manufacturing company.

However, it is not about the cost. But it is about the critical importance of tools in the success of the industry. Large injection molding projects ensure the follow up of high quality, long-lasting precision molds.

For a perfect tool making process, certain factors play an integral role that includes:

- Firm designing and engineering of tools.

- The injection mold possesses high-quality stainless-steel material that ensures optimal quality, performance, and durability during operation.

- The use of high-quality and state of the art tools for manufacturing the precise machinery.

- Manufacturing projects must follow strict quality standards and tight tolerance in products.

Features of Tool Designing

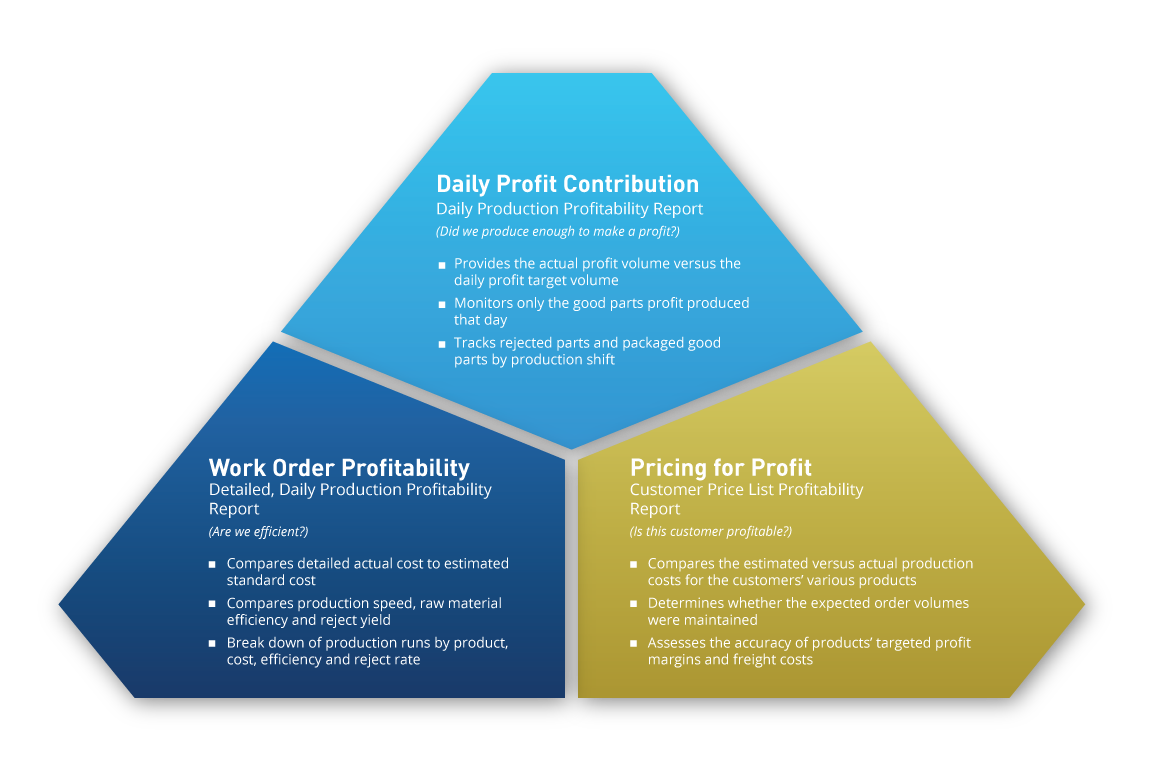

It is an understood phenomenon that in injection molding, the quality of mold plays a central role. It takes a significant amount of investment for any manufacturing firm. Therefore, in an attempt to maximize the ROI in any injection molding project, there are certain elements. These features ensure the availability of maximum profit and yield. They are:

The core of the Metal:

For a perfect mold, the core of the metal must therefore be a stainless-steel material at the core. This is because this metal withstands, for centuries the high temperature and pressure. This happens in long production runs that however, still meets the close tolerance.

Number of Cavities:

The highest level of productivity is due to the presence of a high number of cavities in the mold. This means that a high cavity mold product possesses a highly complex matter. The maximum number of cavities thus ensures the maximum productivity in injection molding.

The Mold Base:

The base makes an integral element in the injection molding. The unit base holds all the major components of the injection mold. This includes cavities of the mold, insert elements, and basic components together.

It also depends upon the size as well as the type of base. Thus, generally, stainless-steel is ideal for producing base. This makes the base capable of making a necessary level of customization.

Machine Design:

This includes the careful customization of molds in the project. This requires careful consideration of the placement of cores, cooling lines, ejectors, cavities, and other such components.

The complexity of the Parts:

For determining the cost of the mold, it is pertinent to consider how complex the mold is. the complexity covers every aspect from the surface to the final part. This also includes the number of cuts and undercuts it requires.

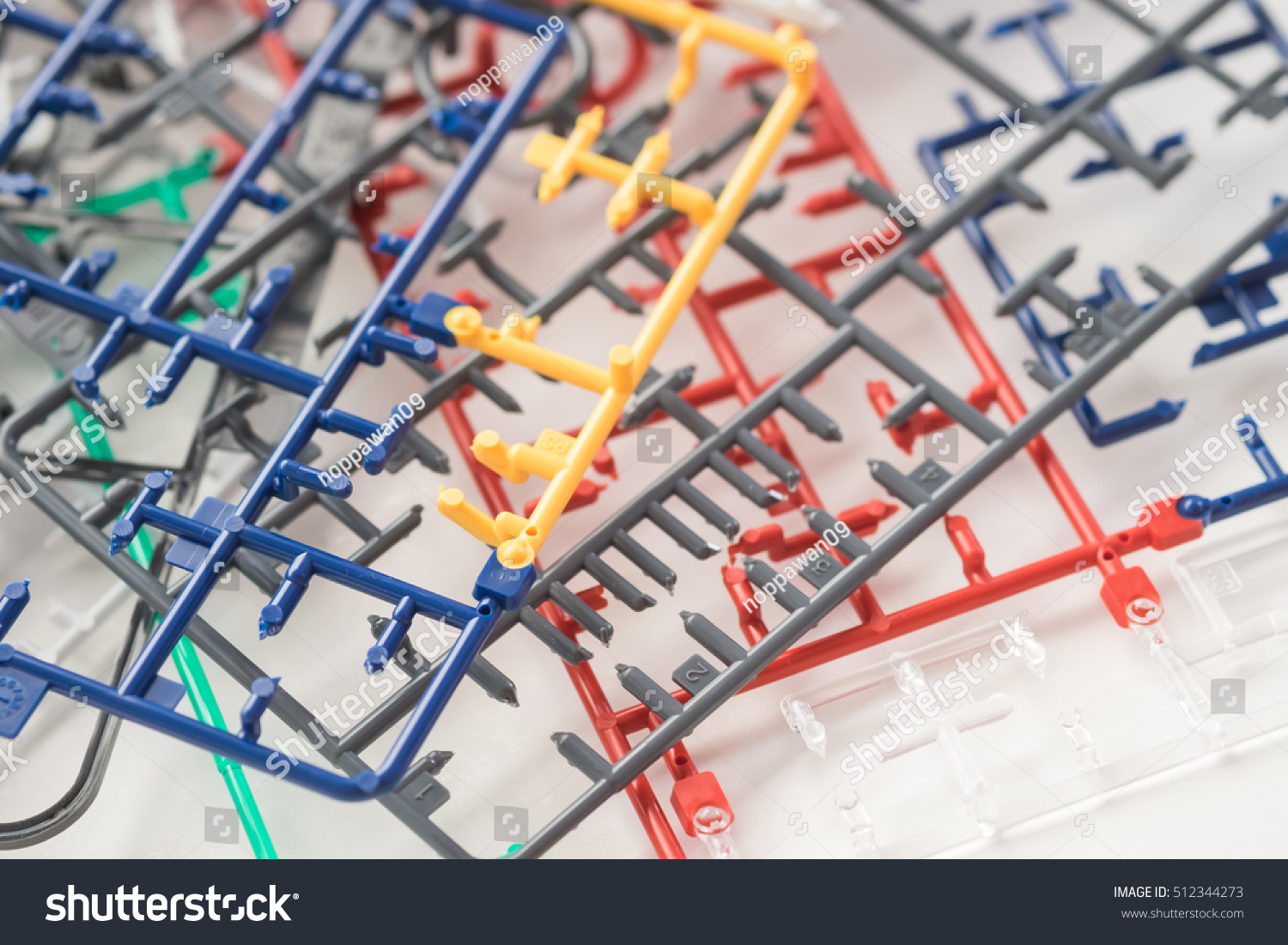

Selection of the Plastic Resin

For acquiring the best quality plastic injection molding parts, the selection of the right material as the resin is critical. It ensures the overall success of the molding process. For this purpose, science makes the selection easier.

The development of polymer science makes it easy for the manufacturer to have a comprehensive assortment. This means that there are a wide variety and choice of selection of resins. This variety allows the manufacturer to feel at ease while choosing the desired quality.

Also, it makes it easier for them to select and alter the strength, and durability of the plastic parts. This is because for each type of resin there are several associated applications.

Production and Quality:

After the selection of molds and resin, next comes the production of plastic injection molding parts. There are several cutting-edge pressers in injection molding.

These edges possess and characterize the variable capabilities and options. The use of the machines surely depends upon the size of the mold. This also takes into account the number of cavities as well as the selected type of resin.

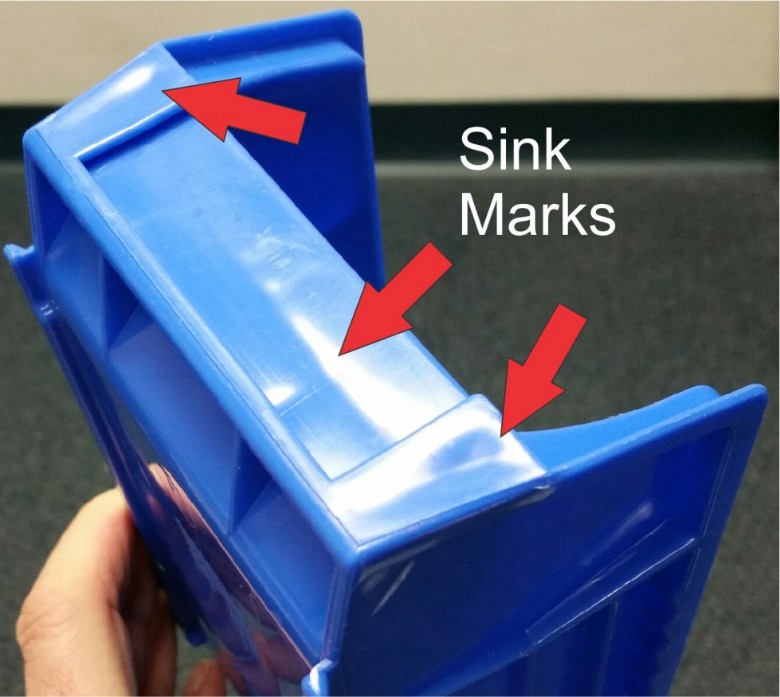

However, some advanced injection molding production units takes special consideration. At this level, they run the sample runs. This sample run ensures the absence of any kind of risk or defects.

You May Also Read: A Comprehensive Guide on Precision Molded Plastics

Final Thoughts:

These key elements are integral and critical for obtaining the perfect injection molding parts. The advanced production units take special care of these features.

This is to make sure that the customer must have the access to the right quality perfect plastic parts. The unit carefully examines these points for successful delivery to customers for every order and every job.

For More Information Contact Us Today!