Soloutions

We deliver integrated in-house plastic solutions that combine industry-leading expertise in high-precision injection molding, world-class automation, and comprehensive project management capabilities. Our approach drives transformation in the medical sector by accelerating time-to-market while maintaining uncompromising compliance with stringent quality standards.

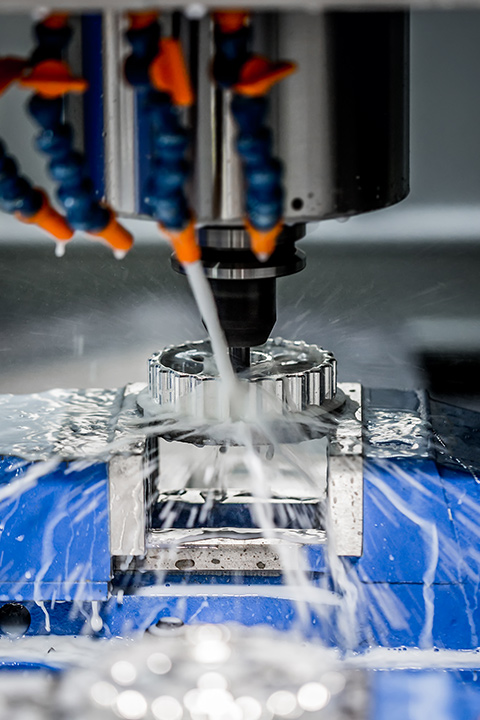

Leveraging precision mold-making technologies and automated manufacturing capabilities, we develop high-efficiency intelligent products for smart office systems, robotics, audio devices, and home automation applications. Backed by extensive technical expertise and a dedicated R&D team, we deliver integrated solutions that ensure premium quality while rapidly responding to evolving market demands.

Through strategic collaboration between Changhong Technology(昌红科技) and Dinglong Holdings, we synergize precision mold engineering with semiconductor industry expertise to manufacture critical components including CMP systems, FOUP/FOSB carriers, and HWS solutions using advanced intelligent production lines. Committed to superior standards and customized services, we contribute to achieving self-sufficiency and localization in the domestic semiconductor supply chain.

Semiconductor Consumables

03