Many small and medium manufacturing units use ERP software for data-management to optimize the output as well as to increase the industrial yield. ERP Software helps a manufacturer in solving the issues of how to make plastic molds in an organized way. Though at first the process of injection molding seems a trivial phenomenon.

However, the process is not as simple and straightforward as it pageants. You may think of it as a project that involves just inserting the plastic risen into molds. It is more than that. The process involves other than popping out the final product and repeating the whole process.

You May Also Read: Plastic Molding in China 4 Injection Molding Defects and Causes

The process, prima facie, looks like a simple method with not much organization. This happens only before you start running the process yourself. However, for large-scale production, the ERP software is integral to injection molding. This is because ERP helps the manufacturer in managing the production assets as well as to increase the yield.

The software also helps in tracking the inventory and ensuring quality control as well.

Before going into the details of how to make plastic molds using ERP, it is imperative to know what ERP. ERP Stands for Enterprise Resource Planning software that helps in managing the managerial issues of production.

Hence it manages and tracks the inventory records, quality control and also schedules the production phases. With the rise in its demand, the software also happens to grow in many versions. Therefore, nowadays, ERP offers multiple versions. It is available in the cloud system as well as IOS/Android version.

This veracity thus helps the management and staff to monitor the system across the organization. However, choosing ERP software for your manufacturing unit must ensure some pertinent elements. The foremost thing to make sure of is that your software must be flexible and dynamic.

Therefore, it must take into account the futuristic perspective also. It should not rather work only for an immediate future.

Well, it depends upon the size of the operation. ERP offers three varieties of software for varying sizes of industrial operations. Some of which are:

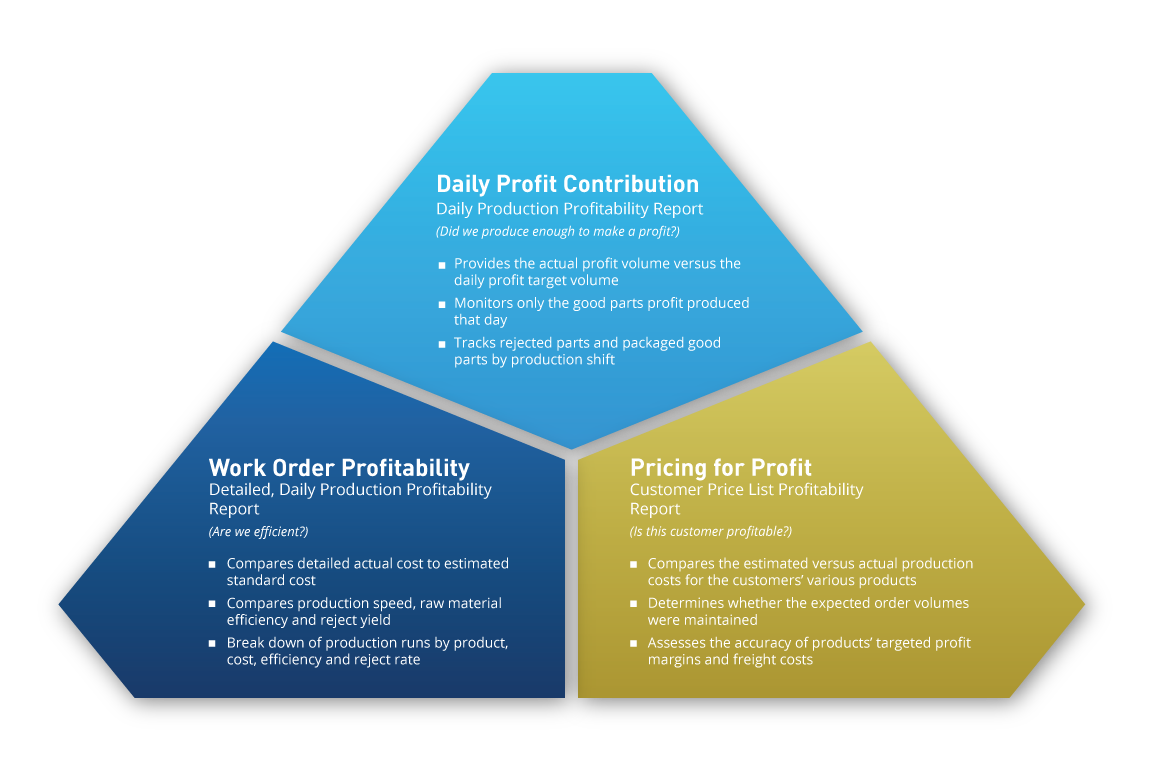

Now, let’s look at how to make plastic molds by ERP software. The primary concern in plastic injection molding the management of the inventory. ERP, therefore, helps in managing the inventory from initiation to the termination of the process. The software hence doesn’t only help in dealing with production schedule tasks.

It will therefore also take into account the process of waste management and production efficiency. The ERP also guides the manufacturers in managing and tracking the consumption of the raw material.

This thus benefits the manufacturers in reducing the left it scraps after the production cycle. This way manufacturers can also make sure to reuse the waste material in the next phase.

Furthermore, the injection molding industry now grows to one of the most innovative industries in the world. This hence asks for monitoring the quality control process for each operation.

The quality operation helps in following the SOPs of operations. As in the case of medical technology, the molding parts must follow the hygiene patterns. To make sure the equipment and instrument must follow the compliant. Quality control ensures the follow up of strict routine on every cost.

Therefore, ERP software helps in maintaining the SOPs by centralizing the process. This centralization guarantees robust management.

Last but not the least, ERP software guides the management on how to increase the production yield and productivity. The software thus manages the vast inventory of the molding material that the manufacturers will inevitably use.

What happens most of the time is that the inventory of prototypes usually goes unmanaged. So, to manage the catalog and avoid the iterations of prototype ERP plays an important task. These steps using ERP proves the systematic structure of the company as a professional.

ERP software is a complete guide to how to make plastic molds innovative and productive. The molding injection industry offers a wide range of plastic products and parts. These parts serve a variety of industries and services.

With varying purposes, variety, and uses, molding injection possesses a variety of production processes. The variety of operations and processes thus calls for a robust system of software infrastructure.

The software hence helps all the injection molding units to manage their scheduling and capacity building. The number of benefits that ERP offers are encouraging and productive.

Digital technology in any form revolves and shapes our lives every day. Not only personal life but also the business structure across the globe turns digital in every aspect. In this era, just participating in digitalization is not a solution for survival.

However, Expanding and reshaping it is the key to success. The real change and development happen when we manage the business and industrial operations using the software.

The ERP software consequently paves way for the industry to act as more organized in Industry 4.0 era. This makes them more competitive and permits them of real-time view o their production, management, and operations.

But the question arises as to how to make plastic molds using ERP as a simple task. Usually, using and managing software in such a large industrial unit is not child’s play. It often is the case that both SMEs and large-scale industrial units work on their information system.

However, this system asks for more effort and hard work to manage the digital task. This requires a complete infrastructure, database, load of hardware units, and servers.

Nevertheless, for Injection molding, ERP cloud operation makes this process simpler. ERP easily connects its data with Microsoft Cloud Technologies. This hence saves a chunk of cash for setting a separate system as a software house.

You May Also Read: Plastic Molding Processing: Industries and Applications

ERP hence acts as the backbone of the injection molding manufacturing. Over time, the software also transforms to offer and handle complex matters.

Hence from molding to compounding and thus thermoforming, ERP is here to guide industries in facing challenges. Therefore, on-time delivery, accuracy, and quality is no more a challenge in injection molding

For More Information Contact Us Today!