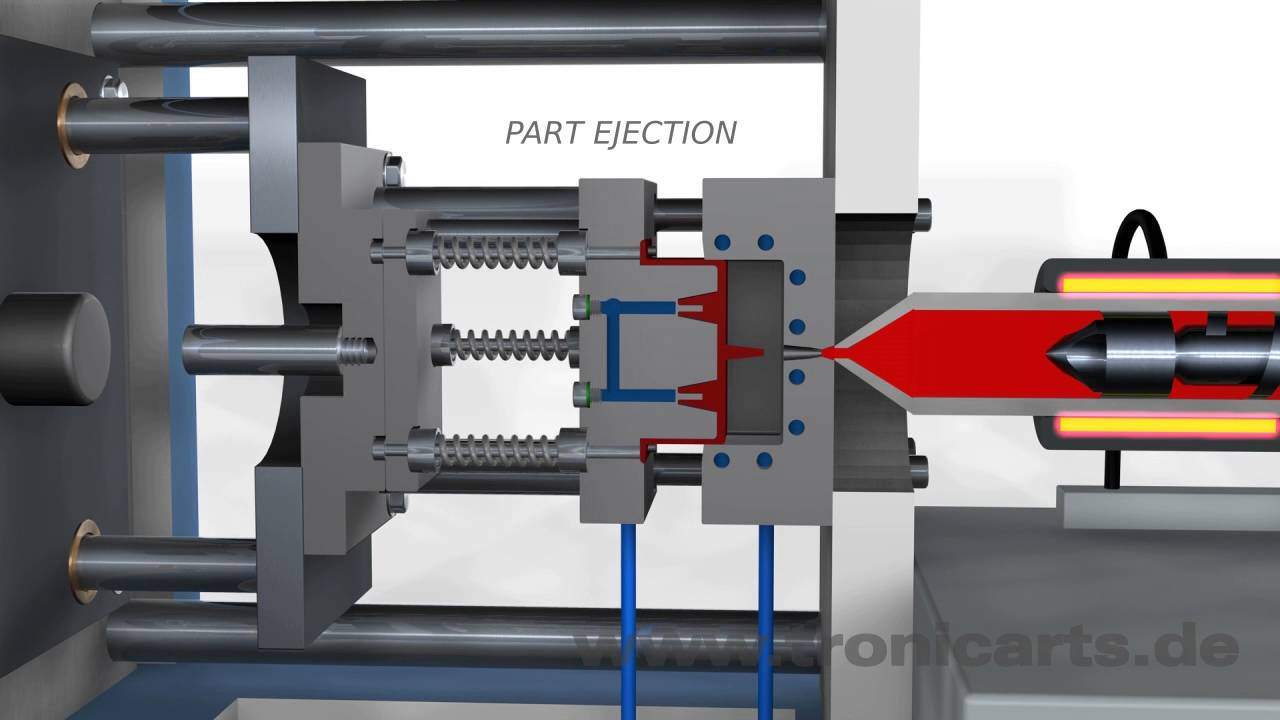

It pushes and squeezes molten materials into an existing farming system called a mold system, then cooling for the liquid material to crystallize and bring the product out.

Such a cyclic process is called an injection molding cycle. The shorter the cycle, the lower the product cost. Therefore, in injection molding, people often calculate the price based on the cycle of injection molding.

Plastic mold system: What is a template?

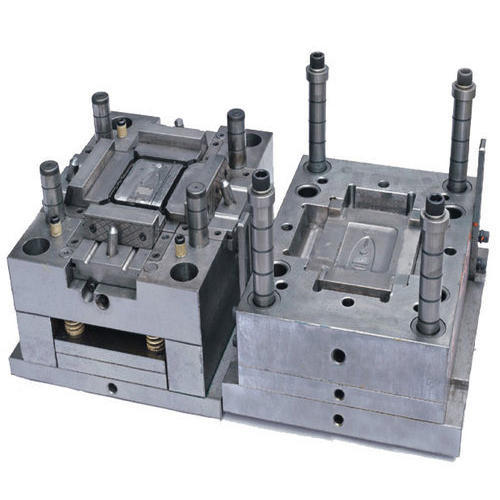

The mold, also known as the mold, is the heart of injection molding technology. The mold is machined and shaped based on the desired product shape. Plastic injection molding factory provides injection molding products. These are shaped by the structure and form of the mold cavity (also known as the core of the mold, the hoe, etc.).

The mold consists of two main parts called the male mold and the female mold. In engineering language and mold manufacturing industry factories. People divide the mold into two parts; mold fixed part and mold movable part.

The fixed part (the female mold)

The fixed part (the female mold) is the part that is stationary during the whole injection molding process. This part is connected to the injection nozzle of the injection machine.

A plastic injection molding factory would inject plastic into the mold cavity. This part includes a fixed part side core, guide shaft, plastic pouring nozzle, fixed mold plate.

This part moves when the mold closes during an injection molding cycle. This part has the effect of extending the mold to take out the product and the runner, then pressing the mold closely. Moreover, the material does not leak out (create three socks) by pressure during the injection process.

In addition to the two main parts that make up the mold, some complex molds also have a sliding platform, a motor system (threading mold), a hydraulic system. A plastic injection molding factory would provide this movable part.

Most of the everyday items are produced by injection molding technology, from simple things like shoe soles to helmets, children's toys, mobile phone cases, candy boxes. Creating molded utensils saves time. It is possible to mass-produce the same in a short time.

Therefore, injection molding technology plays a vital role in daily life. But most of us don't care about the existence of this field.

The plastic injection mold industry currently needs many design engineers, but universities have not yet met them. In a plastic injection molding factory, most of the people working in this field are retrained from mechanical engineers.

In the past, mold design faced many difficulties because there were few supporting industries; however, at present. In addition, the auxiliary mold industry is very developed, so the design and manufacture of molds do not require as much time and effort as before.

How to reduce the cost of making molds?

To reduce the cost of making molds, we must solve and improve the factors that affect the price of molds. If they are an experienced mold maker when they receive a request from a customer, they will:

In a plastic injection molding factory, upon receiving the customer's request, we will directly evaluate based on the technical requirements of the product and give the most accurate and reasonable size to reduce the price of plastic mold to the lowest level.

If the product shape is too complicated, it is necessary to improve the product to simplify the product but still ensure the features and technical requirements of the product.

The volume of the product not only affects the mold cost but also affects the product cost. Many customers are requesting to make products with too thick walls. But it is not necessary for the plastic injection molding factory.

Thick mold walls are not necessarily sound; uneven wall thickness will cause difficulties in the injection molding process such as deformation, concave, shrinkage. Hence, mold makers need to calculate into reasonable products, make thinnest possible to ensure the best product price for the customer. And it at the same time keeps the mold cost down.

There are also several other factors such as the number of cores in a mold, 2-plate mold or core-changing mold, mold material. Therefore, when receiving a customer's request, it is necessary to research to reduce the cost to the lowest for customers. In addition, plastic injection molding factory provides these molds easily.

Plastic laminators are common to pressing and covering paper or photos to prevent water from sticking and keep the product new. In addition, the machine is also common to print on all materials.

The machine can laminate business cards, brochures, plastic cards. Learn more about plastic injection molding machines.

The machine is common in a plastic injection molding factory

Plastic injection molding factory protects your articles with plastic coating. And this incorporation would help in giving you an improved form of the product. It would be a user-friendly plastic injection molding machine with outstanding reliability.

Plastic injection molding factory

Plastic injection molding machine features will create a thin coating, making the pressing happen quickly and easily.

To choose simple, high-quality machines, customers need to pay attention to their user’s needs. For example, notice how often you move? If you drive a lot, you should choose light, simple, and easy to use.