Starting from Lego toys to the high-tech Tesla industry, Plastic Injection Molding Factory is revolutionizing the world around us in a faster and easier way.

Plastic Injection Molding Factory is a method of molding by injecting molten plastic into different molds to shape plastic parts for daily use items. The method is now widely acknowledged as the most revolutionized method of processing and producing plastic products and parts in bulk.

The process of molding plastic originated back in the 19th century. The method was invented in the year 1872 when two manufacturers Isaiah and John Hyatt invented the molding machine to mold plastic.

The molded plastic to manufacture daily used items like combs, buttons, etc. Thus, this first leap proved to a breaking point in the plastic manufacturing industry.

As in today, we cannot think of the world we are in without the invention and utility of modern computers and technology. Similarly, these technological devices would not even exist without the presence of such an advanced, high quality, reliable, and flexible modern plastic molding industry.

Modern plastic injection molding factory paved ways for modern technological devices to step into the real world.

Modern Plastic industry using an injection model is coming up in each passing day with economic, reliable, complex, and quality plastic models and solutions.

These solutions are in daily use for multiple ranges of applications. The molded plastic parts are widely used in every industry because of its durable and reliable nature in terms of corrosion and erosion.

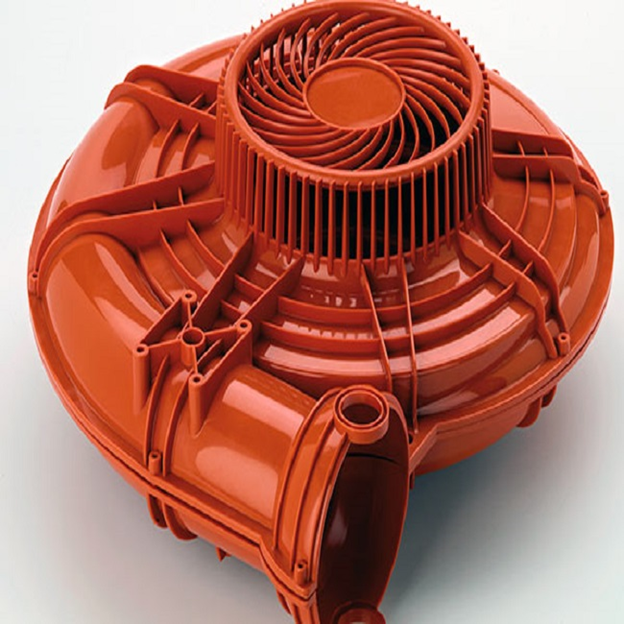

The modern plastic injection molding factory uses a variety of methods and modern techniques of injecting plastic into complex and highly detailed molds.

It creates a complex plastics design with several details and features. The basic working model of the injection molds uses high pressure as its main subject. This, thus, exposes plastic to hard press, which helps in getting the complex and desires shapes/designs in real-time.

As opposed to the conventional molding method, the modern molding industry makes it easier for the plastic to get in shape by creating intricate designs and shapes.

This method in plastic products comes up with such precision that it is impossible to think of in using the conventional methods of plastic molding.

The level of precision in the plastic injection molding factory is extremely accurate. A single manufacturing unit can easily fabricate a plastic model of any type to a level of 0.001 inches.

This process is known as precision molding. The process is completely automated. Therefore, it remains inexpensive for the manufacturers even if they are to develop the most complex designs. Yet, this is the most sophisticated method of molding complex and reliable designs in the market.

The process of precision molding differs largely from the conventional molding machines. This is because conventional molding machines lack such detailed precision, quality, and durability in design. Whilst, precision molding includes complex geometric in manufacturing the complex, precise plastic molds.

The nature and use of plastic have changed over time. The plastic injection molding factory has revolutionized the plastic products that contain high quality, durability, and precision as the basic elements in all items.

The conventional methods of manufacturing produce hard and heavy plastic products. Whereas, the modern molding techniques and technology using injection have enabled the industry to design lightweight products. But these are stringent materials that last even in the most rugged weather having extremely hot /cold conditions.

The modern injection methods are making it possible for the manufacturers to add the fillers in injection molds. These fillers are missing in the conventional methods of plastic molding. These fillers like calcium, silica, clay, etc., thus add quality and variety of strength to plastic depending upon the usage.

The strength and stiffness of the plastic material increase using fillers. However, it also helps in decreasing the overall density of the plastic material, thereby reducing the weight and bulk of the final product. Lightweight and high strength are what injection molding is all about.

Furthermore, manufacturers use fillers in order to increase the heat resistance of products. Small plastic parts used in various industries like auto manufacturing or kitchen products need durability and flexibility.

This is because such products usually face high/low temperature and pressure. Manufacturers use Nylon (Polyamide) for quick-release buckles and passenger seats in public transport. For refrigerators, manufacturers use Acrylics as refrigerators store food at low temperatures, and for knife handles, they use polyoxymethylene (POM).

Whereas, the traditional method of molding plastic using lacks these characteristics and has its own limitations both in production and designing. The modern methods of injection molding are versatile and are also equipped with bulk production.

Plastic injection molding factory, considering the prevailing environmental degradation, is one of the sustainable manufacturing industries. As known, plastic is one of the non-biodegradable materials which is causing and destroying the ecological setup of the global world.

The conventional method of plastic molding involves the cutting of large plastic pieces into smaller ones leaving a large amount of plastic solid waste material.

In addition, injection molding is an automated process that involves a minimal amount of human labour. The invention of modern machinery to perform molding using computer-operated machines and robots has revolutionized the plastic world. This thus makes injection molding a cost-effective process.

Unlike the conventional method, which involves human labour, the injection method reduces the labour incentive. The injection molding units use software and technologies like CAD and CAM. The ability of the system to design precise and accurate design in one go.

This makes the product ideal, thereby reducing the chances of recreation. It also reduces the cost by 25 times as compared to the conventional method.

You May Also Read: 6 Benefits That Would Make You Want to Automate Your Plastic Molding Process Today!

It goes without saying that plastic injection molding is the most popular method of plastic production.

The foregoing points are some of the benefits that the modern system is offering. Therefore, this is the best method that offers durability, precision, creativity, and is cost-effective.