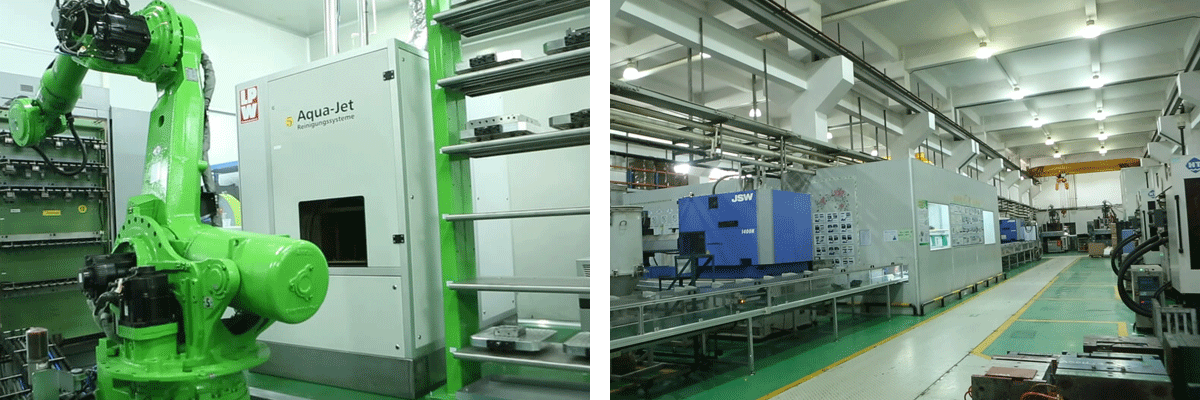

Manufacturing ABS plastic parts with custom machining service. Acrylonitrile Butadiene Styrene (ABS) is a light yellow or milky white plastic and popular, budget-priced engineering material that suitable in turning, milling, lathing, drilling, cutting, injection molding, and more. With good machinability, weldability, high impact strength, tensile strength & stiffness, chemical resistance, mechanical toughness, excellent dimensional stability and more properties, ABS plastics and ABS machining products are often used to make lightweight solid products for mechanical, food equipment, aircraft, oil & gas, medical technology, alternative energy, conveying and more fields.

| Material | PC, ABS |

| Tolerance | +/-0.05mm |

| Surface Treatment | Anodizing, chrome plating, silver plating, polishing, galvanized, electroplating, passivation, powder coating, spraying, and painting, etc. |

| Main Process | Turning, lathing, milling, drilling, grinding, boring, stamping, threading, tamping, EDM, wire walking, laser cutting, laser marking, and surface treatment. |

| Quality Control | Strictly Quality control in the whole process, from material to packing Industry CT scanning, 3D projector, X-ray technology, Coordinate-measuring machine |

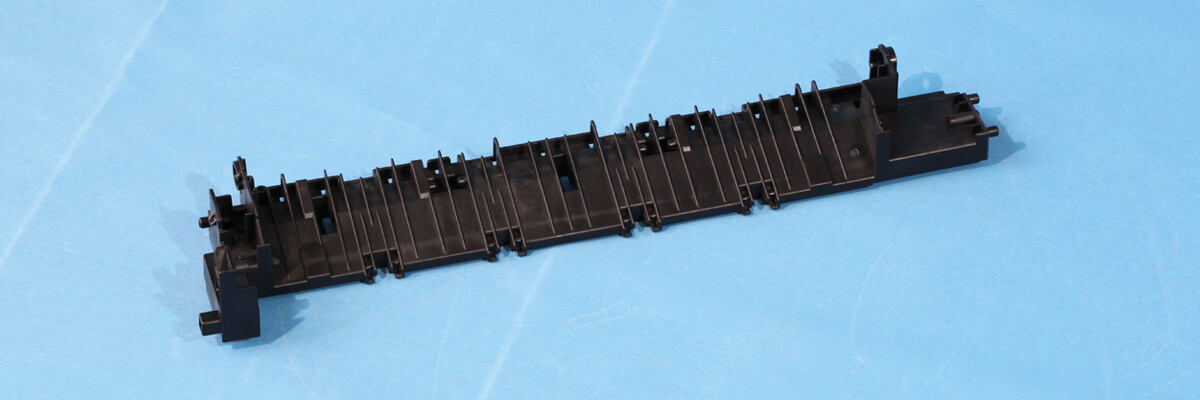

| Application | Office Supplies |

| Function | Internal mechanical transmission of paper products, guiding effect |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

Our professional engineering and production team will help you find the best solution, and produce the desired parts in a cost-effective and highly efficient way. Please call us +86-755-8978-5568 or email sales@sz-changhong.com.

4. Do you do the surface treatments please?

Sure. We do the surface treatments, like screen painting, laser etching, thermal melting, welding as well as assembling.

5. What drawings format you need for production?

2D, 3D both available. 2D like PDF, CAD, JPG etc. 3D like STP, IGS, STL, SAT, PRT, IPT etc.

6. What about quality control?

Self-inspection in every process by the production operator. Spot inspection and final inspection executed by QC, Defective rate is controlled within 1%.

7. What kind of payment terms do you accept?

T/T, Acceptance.

8. What's your largest advantage?

We specialize in high precision mold with professional technical team and quality guarantee and management.