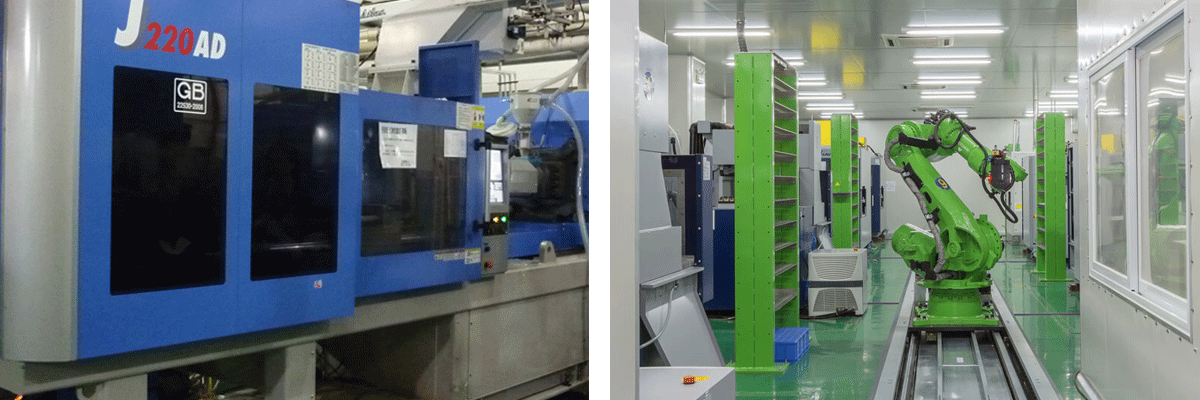

Difficulty: Filter and plastic injection molding, multi-cavity mold 1×64, the accuracy and positioning requirements of the insert are accurate, the fit of the 64-cavity back mold and the 64-cavity front mold must be accurate, and space for the mesh to be placed in the subsequent production Automated very precise process.

Injection molding is the most common modern method of manufacturing plastic parts. It is used to create a variety of parts with different shapes and sizes, and it is ideal for producing high volumes of the same plastic part. Injection molding is widely used for manufacturing a variety of parts, from the smallest medical device component to entire body panels of cars. A manufacturing process for producing plastic parts from both thermoplastic and thermosetting materials, injection molding can create parts with complex geometries that many other processes cannot.

| Material | PP frame, nylon mesh |

| Size | 40um/70um/100um |

| Color | Yellow, Blue and White |

| Application | Lab |

| Certificate | ISO |

| Service | OEM |

Our professional engineering and production team will help you find the best solution, and produce the desired parts in a cost-effective and highly efficient way. Please call us +86-755-8978-5568 or email sales@sz-changhong.com.

4. Do you do the surface treatments please?

Sure. We do the surface treatments, like screen painting, laser etching, thermal melting, welding as well as assembling.

5. What drawings format you need for production?

2D, 3D both available. 2D like PDF, CAD, JPG etc. 3D like STP, IGS, STL, SAT, PRT, IPT etc.

6. What about quality control?

Self-inspection in every process by the production operator. Spot inspection and final inspection executed by QC, Defective rate is controlled within 1%.

7. What kind of payment terms do you accept?

T/T, Acceptance.

8. What's your largest advantage?

We specialize in high precision mold with professional technical team and quality guarantee and management.