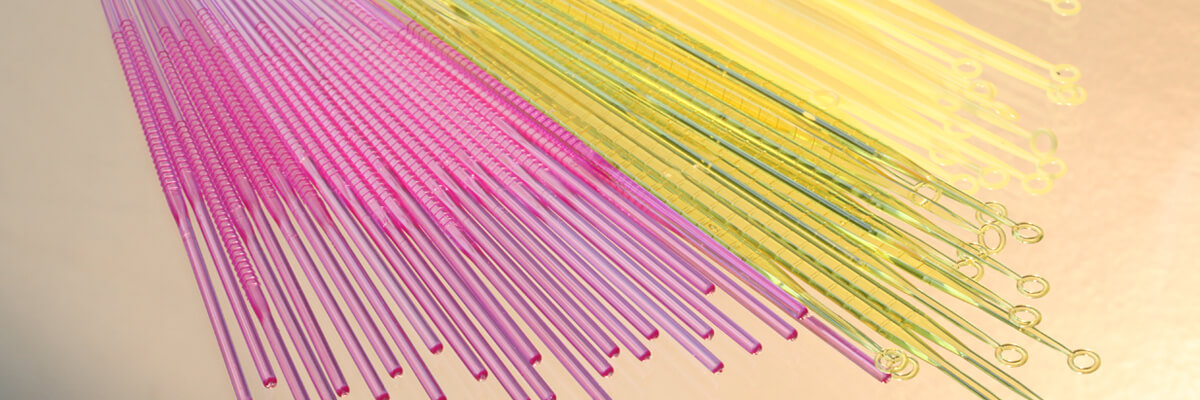

The disposable inoculation loop and inoculation needle are made of polystyrene, and the surface is treated to be hydrophilic, suitable for microbial experiments.

| Material | Disposable medical consumable PP material |

| Surface | Bright, Polished |

| Tolerance | 0.003-0.05mm |

| Size | As customer's request |

| Service | Customized |

Our professional engineering and production team will help you find the best solution, and produce the desired parts in a cost-effective and highly efficient way. Please call us +86-755-8978-5568 or email sales@sz-changhong.com.

4. Do you do the surface treatments please?

Sure. We do the surface treatments, like screen painting, laser etching, thermal melting, welding as well as assembling.

5. What drawings format you need for production?

2D, 3D both available. 2D like PDF, CAD, JPG etc. 3D like STP, IGS, STL, SAT, PRT, IPT etc.

6. What about quality control?

Self-inspection in every process by the production operator. Spot inspection and final inspection executed by QC, Defective rate is controlled within 1%.

7. What kind of payment terms do you accept?

T/T, Acceptance.

8. What's your largest advantage?

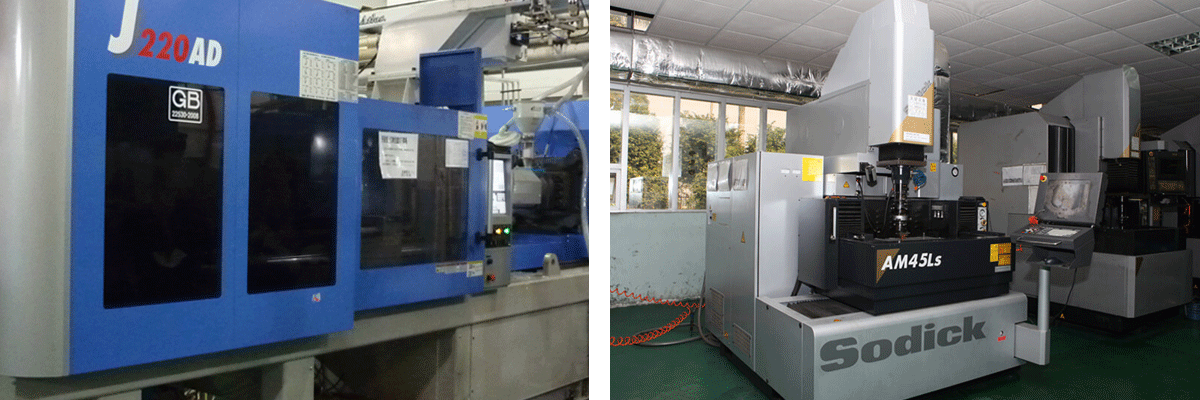

We specialize in high precision mold with professional technical team and quality guarantee and management.