CHT, as a precision contract machine shop, offers unparalleled precision with a fast and cost-effective method for producing high quality plastic parts. While equipped with advanced precision machining centers, our company provides very precision machining parts and services.

Machining is a process used in the manufacturing sector that involves the use of computers to control machine tools. Tools that can be controlled in this manner include lathes, mills, routers, and grinders.

Machining is a manufacturing process that allows for increased efficiency through higher levels of automation and by allowing the machine and it’s computer controls to do all the work. As you can imagine, machining provides a variety of advantages in custom machined parts.

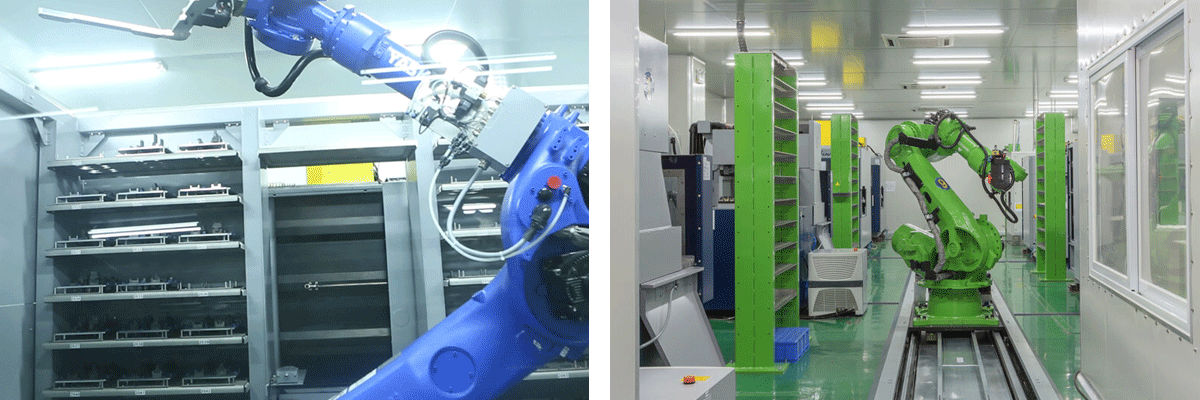

Automation: machining removes the need for an operator for all but a few parts of the work. Machines can be left unattended for hours or even days if necessary, allowing operators to focus on other tasks.

Repeatability: Once a design has been fed into the computer, the machine can repeat the manufacturing process multiple times. Also, you will always get a high level of precision in the component.

Range of Materials: machining can be used to manufacture products from a variety of materials. These include bronze, steel, aluminum, as well as gold and silver. Polymers such as ABS, polycarbonate, and PTFE can be used with the machine as well.

Flexibility: A machine can be completely reprogrammed in a matter of hours to produce a completely different product.

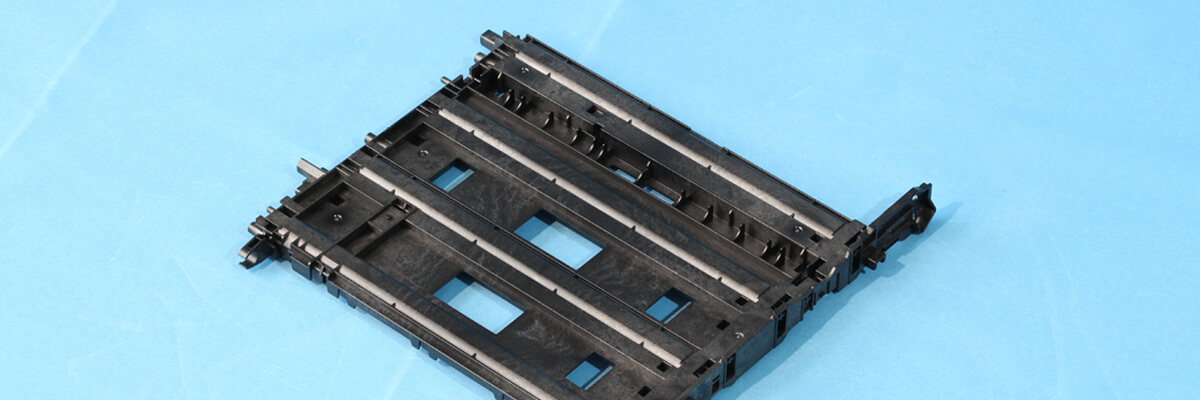

| Material | Plastic |

| Tolerance | +/-0.01mm |

| Drawing Format | CAD, STP, ETC, PDF |

| Structure | Single-side Bracket |

| Service | OEM, ODM |

| Certification | ISO9001: 2015, IATF16949, ISO13485, etc. |

Our professional engineering and production team will help you find the best solution, and produce the desired parts in a cost-effective and highly efficient way. Please call us +86-755-8978-5568 or email sales@sz-changhong.com.

4. Do you do the surface treatments please?

Sure. We do the surface treatments, like screen painting, laser etching, thermal melting, welding as well as assembling.

5. What drawings format you need for production?

2D, 3D both available. 2D like PDF, CAD, JPG etc. 3D like STP, IGS, STL, SAT, PRT, IPT etc.

6. What about quality control?

Self-inspection in every process by the production operator. Spot inspection and final inspection executed by QC, Defective rate is controlled within 1%.

7. What kind of payment terms do you accept?

T/T, Acceptance.

8. What's your largest advantage?

We specialize in high precision mold with professional technical team and quality guarantee and management.