Do you want to make plastic parts yourself? But you don’t have investment for a massive plastic molding machine or a CNC 3D printer? With all the components that come with a plastic molding kit. You can easily make plastic parts at your home or workshop. Without spending thousands of dollars on expensive machines.

A plastic molding kit contains everything you need to mold all sorts of plastic parts at home. While a plastic sample kit can help you choose the best type of plastic for your application.

In this article, we will talk all about plastic molding kits, their benefits, and the components that come with them.

Many kinds of plastic molding kits are available, with each kit designed to tackle a different scale of the project. But a typical plastic molding kit may contain the following components:

Each of these components has an important contribution to the entire plastic molding process. We will discuss them in detail below.

But for the uninitiated around here, let’s first understand the process of plastic molding.

Plastics have taken over the world. Look around the room you are sitting in. I bet you can find at least ten things that are made out of plastic. Plastics gained popularity in the previous century. And with plastics becoming prevalent came the popularity of the plastic molding process.

The majority of the plastics that are used commercially, industrially, or domestically are made through the molding process. In this process, plastic is first melted, if it is in resin form and then cast into a plastic mold. Or if it is in the form of liquid plastic resin then it is directly cast into the mold.

The molding process comprises a mold that has a cavity in the shape of the desired plastic part. When the machine or human molder extrudes or casts the liquid plastic into the mold, it fills the cavity. Once the liquid plastic cools and solidifies, it takes the shape of the cavity. And the finished plastic part, now in the required shape, is removed from the mold.

Granular plastics are normally used in injection molding processes that use injection molding machines to cast molten plastics into the mold. While liquid plastic resin usually serves in the manual casting and molding process.

A plastic molding kit is bringing the plastic molding process out of industries and taking it into the home and workshops of polymer-parts enthusiasts.

A typical plastic molding kit comprises all the necessary tools, materials, and equipment for making parts at home. Thus, being more affordable than bigger machines, a plastic molding kit allows you to create all sorts of parts without having to invest in injection molding or 3D printing machines.

Apart from being an easy investment, a plastic molding kit offers numerous other benefits that make it a favorite among most molders. Some of the benefits include:

You are brainstorming for a good custom-made present for your friend. You want to get something that is personal and affordable. If you have a plastic molding kit, you won’t have to spend hours upon hours thinking about places that can make custom presents for you. You can make a cute, personalized gift yourself.

A plastic molding kit enables you to create all sorts of parts, from small key-chain charms to bigger parts for more significant projects. All you have to do is find a good kit and get molding. Who doesn’t love DIY?

A plastic molding kit is a one-time investment. Apart from allowing you to create custom plastic parts, it also saves you a lot of money and generates a quick return on investment.

With a plastic molding kit at home, you don’t have to set out into the market looking for plastic parts for your projects like DIY house renovation for which you can mold plastic scrappers and brush mats. With the right polymeric resin, from arts and craft supplies, toys, and parts for your automobile, there is no part that you cannot make with this kit.

Consumers and makers love plastic, but the environment doesn’t. Hence, recycling plastics is imperative to preserve our natural ecosystem.

A plastic molding kit provides you with an opportunity to recycle waste plastic at home. All you have to do is melt used plastic parts (bottles, containers, etc.) and cast them into the mold that comes with the kit. In this way, you can play your part in saving the environment and recycle some of your plastic waste at home.

As we mentioned in the beginning, each component of the plastic molding kit contributes to making the parts creation process. In this section, we will discuss the role of each of these components in detail.

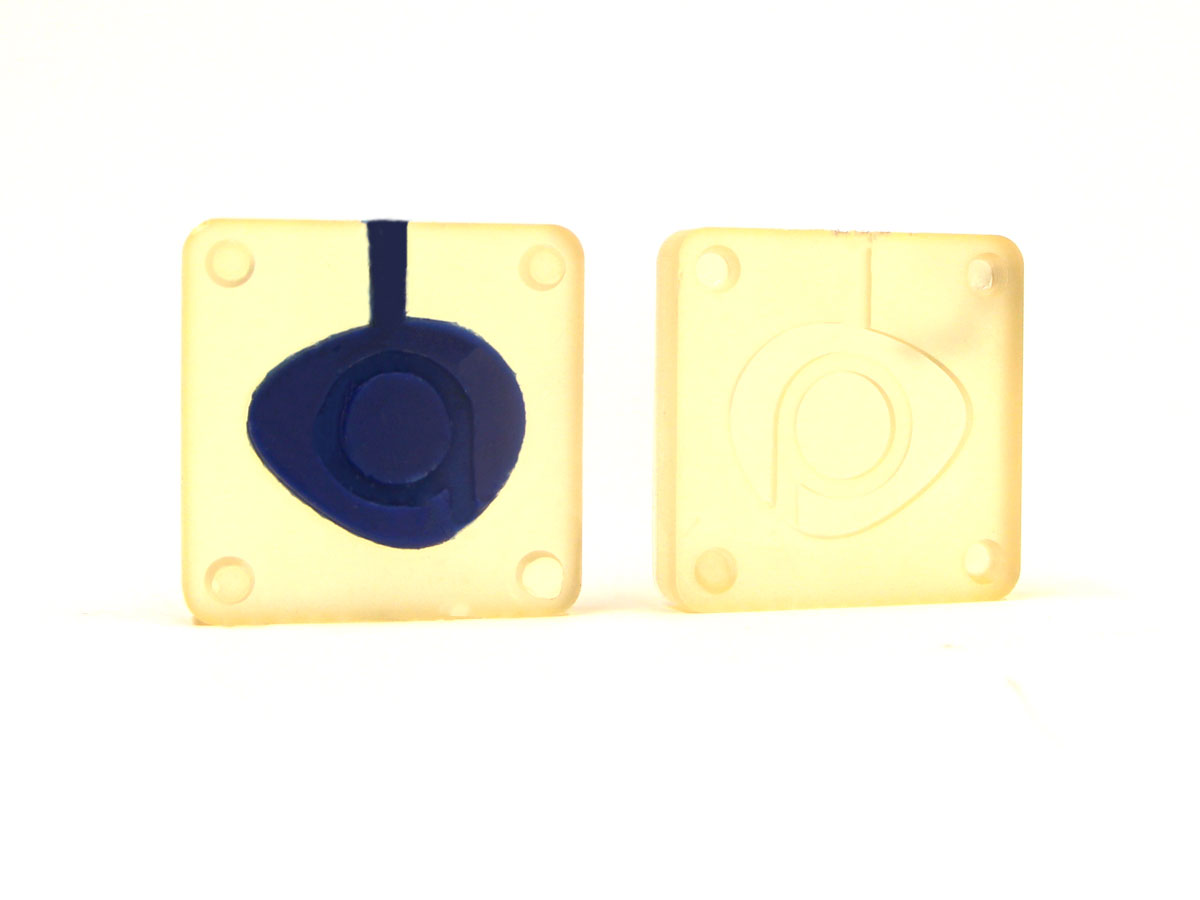

A plastic molding kit may come with a frame or a mold. A mold will have a pre-made mold cavity and will restrict you to just one type of plastic part. On the other hand, if you get a kit with an aluminum frame, you have the option of modifying the frame using epoxy putty and creating new mold cavities every time you need a unique plastic part.

The frame or mold comes with a sprue that is the entry-way of the molten plastic. It also has to align pins that aid in clamping and sealing the mold shut during the casting process.

Most plastic kits may as well come bearing a suitable plastic to help you create your own plastic parts at home.

If you are buying a kit with an injection molding machine, you will probably get solid plastic resins that the machine will melt and mold. However, if you have invested in a kit for manual molding, you might get liquid plastic that you can mix and pour into the mold, wait for it to solidify, and get your own plastic part.

A mold release is an important part of the plastic molding process. It ensures that the plastic part comes off the mold easily.

Like you use butter to grease the cake pan before pouring in the batter to make sure that the cake does not stick to the pan. Similarly, you must spray the mold release inside the mold before pouring the molten or liquid plastic. So that it leaves the mold without sustaining any cracks or damage after it is solidified.

The solidified plastic part, after you remove it from the mold, has uneven edges and rough finishing. So, the plastic molding kit comes with razor blades, sandpapers, and other finishing tools that can help you remove to create a plastic part that is smooth and perfectly finished.

When it comes to plastic molding, you have a wide variety of plastics to choose from. And once molded, each type of plastic performs differently. So, to ensure that the plastic that you mold with performs nicely in your application, you must get your hands on the right type of plastic.

A plastic sample kit comes in handy in this case. It carries parts molded from different types of plastics so that you can see how each type of polymer will behave post-molding and choose the most suitable plastic for your application.

A plastic molding kit helps you create customized plastic parts that you can use in a wide variety of applications, from DIY house renovation to customizing automobile cars. Moreover, investing in a kit also enables you to make your own parts and prevent spending your money on market-made plastic parts.

![]()

Coming with many components, this kit contains everything that you need to create your own plastic parts at home. While also allowing you to recycle waste plastic at home by melting and remolding it in the kit’s mold.

For More Information, Contact Us Today!