We can say that three main factors directly influence the quality of the molding plastic at home: the mold, the material (raw material), and the process. We'll talk about them in this article. Also, get to know some points of attention that are needed during the injection process

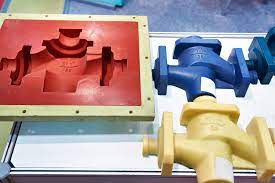

The plastic injection molding machine is easy to influence by items such as distribution channels, cold wells, and temperature uniformity. Composed of steel, the mold tool can contain mobile or stationary plates, which define the shape of the produced part.

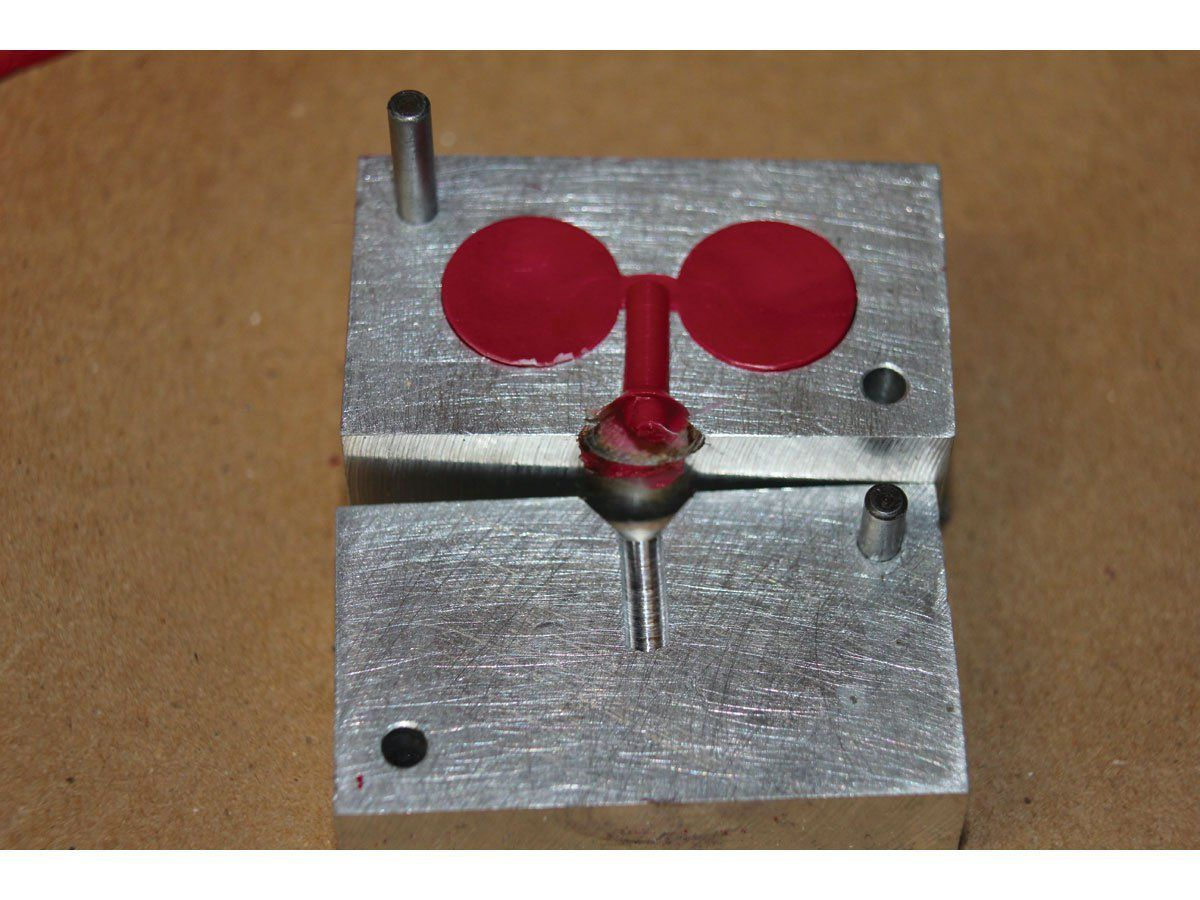

The final material is then pushed out of the mold via ejector pins. A coolant (usually water) passes through the material to remove some of the heat and prevent overheating. For molding plastic at home not to impair the proper functioning of the mold, it is important to consider the following items:

These are responsible for transferring the molten material from the nozzle to the cavity inlets.

It serves to absorb the colder flow in front of the material. The machinery is usually composed of a primary cold well and a secondary one. See below for an example of a cold well distribution channel. This links to molding plastic at home

It is in the mold that the final part is created; that is, it is necessary to pay attention to quality throughout the injection process. The temperature has a great influence in this sense, as it can interfere with the part's finishing, internal tensions, dimensional stability.

Mold protection is worth mentioning that all injection molding machines include mold protection from the oldest to the newest. When done properly, it helps to ensure efficient injection of thermoplastics.

It basically requires the operator to check the position of the mold and adjust its pressure and speed. reduced.

Initially, it is necessary to carry out a previous and detailed study of the thermoplastic resin to be common, according to what you want to obtain as a final product. In molding plastic at home remember that each resin belongs to a family, which in turn counts certain amounts of grades.

First, it is important to know that the drying time of the molded material directly affects its final strength. Thus, once the ideal drying time is respected, the greater the resistance of the piece. Another highlight of molding plastic at home is the temperature and pressure common in the injection process.

Each step requires a certain temperature to work well. As we can see, the higher the temperature, the more there is contraction and degradation of the material. Likewise, the holding pressure influences the filling and burr creation of the parts. Pay attention to the ideal balance for safe, quality plastic injection.

As you can see, there are many more variables involved in the injection process than mold and raw material/material variables. Therefore, it is necessary to be extra careful with the process to guarantee the quality and performance of the final product.

In addition to drying time and material temperature, pay attention to mold temperature control, rework after injection. Apart from these in molding plastic, temperature control and cavity filling, in the case of molds with hot runners, also link.

A good, molded part requires basic principles such as knowledge of the physical properties and processing characteristics of the material, in addition to adjusting the equipment at the appropriate temperatures for the cylinder and mold.

For example.

A fast-cycle part calls for lower temperatures, especially in the mold.

Listed ahead are 4 considerations for molding plastic at home

To achieve greater precision in the positioning of the spindle and repeatability in the metering volume, it is generally advisable to adjust the metering profile with higher initial speeds. This number decreases as the cylinder is loaded and during cooling to increase cylinder life and prevent raw material degradation.

It is also necessary to control the backpressure, which allows for greater homogenization and gas elimination. Its poor management can lead to degradation, breakage of the molecular chain, detachment of fibers, or even a reduction in the useful life of the cylinders.

Generally, molding plastic at home's pressure must be scaled down. In this way, when the injected solidifies, internal tensions avoid. However, this must come with caution because sudden drops before the gate freezes can cause the material to return to the cylinder, which causes material reorientation.

Good results also involve the safety of plastic injection molding operators. Therefore, it is important that your company is aware of and adequate to the security requirements.

By being careful with all these variables of molding plastic at home (involving a plastic injection process), it is possible to achieve excellent results in the parts produced. In this sense, the search for knowledge, constant updating, and security are essential points that make the difference in positioning your company in the market.