Also called "plastic injection", injection vacuum molding plastic is a process for using thermoplastic materials to create different types of parts. This is a manufacturing technique increasingly common in industrial firms. It will therefore be useful if you want to launch your industrial project. Here are a few advantages.

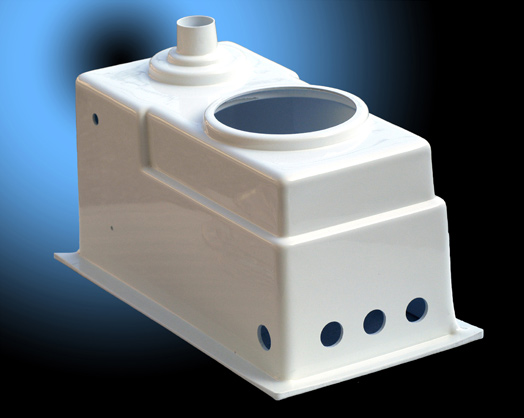

The first advantage of injection molding is to promote the large-scale production of difficult-to-design parts. In fact, plastic injection is a high-precision process which makes it possible to reproduce very complex parts by pressing the plastic into the mold. This process makes it possible to generate any type of shape.

The technique of plastic injection molding is also suitable for vacuum molding plastic. In fact, it is a rapid production technique that allows a high completion rate to be achieved in record time. However, note that the production speed depends on the complexity and size of the part to be reproduced.

Injection molding meets the need for product longevity which increasingly characterizes the industrial sector. Indeed, in order to manufacture more durable parts, metals are increasingly replaced by thermoplastic materials, common in plastic injection method. This makes it possible to create pieces that are both light and resistant.

Also, note that injection molding can produce parts with dimensional accuracy that no other process can achieve. The use of vacuum molding plastic makes it possible to obtain this accuracy of measurements which is essential in the final assembly of the parts. The surface of the parts also benefits from this high dimensional precision to give the desired look and feel.

Besides, the use of injection molding as a production technique has an ecological advantage. Indeed, this technique helps to limit the production of plastic waste, given the small amount of material common. Finally, with plastic injection, waste is easy to recycle, which considerably reduces environmental pollution, a problem that is still worrying in the industrial sector.

By promoting the use of various types of plastics, the vacuum molding plastic technique has a great advantage of flexibility and therefore freedom in the design of parts. Thus, the choice and the adjustment of the appropriate materials favor the production of perfect parts.

Also, be aware that the injection molding method has several economic advantages. First, this technique allows companies to save both manufacturing costs and labor costs. We explain this by the fact that the same materials are easy to recycle and common several times and also by the use of robotization of production.

1 – Sustainability

Currently, sustainability and conscientious actions that aim to preserve the environment are being inserted in different segments, since the future of the planet depends on responsible actions taken today. The vacuum molding plastic market is no different: the main objective is to reduce the emission of polluting gases into the atmosphere and reduce waste and debris that go to landfills.

Sustainable actions go beyond just a good logistical speech, but directly affect, in a positive way, the environment and the health of living beings. There are even specialists who offer sustainable solutions efficiently, such as: the replacement of non-recyclable materials with recyclable options.

Improper disposal of plastics considerably harms the environment. This proposal allows the production of all materials through the injection of plastic, allowing it to be 100% recyclable.

The inclusion of biodegradable materials, such as bioplastics, is already a reality; the trend is that in the year 2021 this alternative will increase.

The bio plastics use renewable biomass in its composition products, enabling its decomposition does not harm the environment. We estimate that vacuum molding plastic will grow on average 20% next year. Packaging develops with raw materials such as sugar cane and cassava.

2 – Technology

Plastic injection molding is not something new in this market, but the increase in production still brings great benefits to this segment. Through it, it is possible for the pieces to gain more value and become more accessible. Currently, technological trends have offered significant changes in this sector; the insertion of automation software allows for a safe analysis of the plastic flow.

The year 2020 comes by changes in the way of buying, selling and producing. With social isolation, companies and consumers discovered that it was possible to continue producing and buying. Technologies were great allies in this period, and the trend is for them to remain in the year 2021. It is noteworthy that the focus on sustainable vacuum molding plastic will still be a priority.

3 – Projections for the future

If you've come this far, you could understand that the projections point to significant changes in different sectors. The plastic molding market is no different. Conscious actions aimed at developing green technologies are already a reality.

Studies and research claim that these actions will increase. On the other hand, the use of disposable plastics that harm the environment will be reduced.

The shrinkage of the Vacuum molding plastic is related to the specific volume. As the pressure in the cavity increases, the specific volume decreases. As the pressure of the plastic in the cavity increases, the effects of contraction of the part reduce.

An unbalanced mold is reflected in:

The cavity that you fill first may end with burrs and the rest of the cavities remain less.

In summary, as a good process technician you must make sure that the mold you are injecting meets a good balance. This is easy to do through fill studies and verify the variation or standard deviation does not exceed the limits allowed in injection molding.

Vacuum molding plastic applications that are reusable and recyclable are environmentally friendly alternatives that bring benefits to this industry.

If you believe in this change, insert these innovations into your company and look for new alternatives. A look to the future implies conscious attitudes today. Through this article, you could see how much actions like this are necessary and important for everyone.