Creating fishing plastic molds through injection molding is still a relatively understudied subject. Fishing molds are one of the many experiments conducted within the injection molding industry. The plastic injection molding industry uses heavy machinery and expert technique while creating molds.

The large-scale molding machine costs a hefty amount, it suits the industrial sector more. The plastic injection molding procedure follows distinct steps however you can try these out at home. The injection molding process begins with liquid resin and ends up with a hardened surface.

Furthermore, the changes and personalization that you can perform with these injection molds are endless. Release your creative skills while making plastic molds.

Fishing plastic molds will cater to plastic fishing products such as hooks and needles. A clean and precise molding job will ensure that the product works the best in the long term, messy molding jobs can make the product hollow from the inside.

The fishing plastic molds include soft baits for capturing fish. The softened exterior makes the bait easier to float. Moreover, the softer side will easily hook the fish forward. You do not have to purchase the lure online or even through stores, create your lure at home.

A small-scale plastic injection molding is quite common for those who wish to fish every day. The fishing lure can cost a lot when this becomes your job, making your own lure with the plastic injection molding process will reduce the overall costs. This cost-efficient method is also very safe for the fish and the creator.

Crafting your lure depends on how you want it to look. The plastic injection molding series shall begin when you determine what type of lure you want. Silicone is a common variable while creating plastic molds.

Generally, silicone is classified as plastic that looks and feels soft. Silicone products do not damage easily moreover they are a durable alternative to harsh lures. The silicone lure can easily attract with any instrument moreover a silicone injection mold is the easiest to make out of other plastics and aluminum. A silicone plastic mold can create hundreds of lures at one time, this works best in the open mold strategy.

A newbie performing plastic injection molding should stick to the closed mold in case of any spills. The closed mold will do most of the work for you. You can inject the liquid silicone or aluminum inside the closed mold and wait for the magic to happen.

An open mold requires a harder technique and a steady hand. The open mold method is not suitable for those who are just getting the hang of plastic molding therefore closed injection molding takes the win.

The fishing plastic molds process occurs in a series of steps; you will never go wrong while following them. Before the molding procedure begins you must have the proper cavity to hold the molds.

The lure cavities found in the market have the same basic structure and no ingenuity. Creating the plastic mold cavities at home will help you change the designs later on. You do not have to restrict yourself to only one mold size.

The cavity construction procedure takes longer than the injection molding process. The accuracy of the cavity and its measurements will determine how sleek the mold will turn out.

The first and most obvious step will include making the shape with clay. Any kind of transparent or soft clay will do the job, employ your artistic skills by rolling the clay out into shapes. The lure shape looks like a basic fish, no need to add a lot of details.

You can alter or paint these lures later for an additional effect. Sculpt the clay according to your preference and size. Once you sculpt the lure size to perfection, lay these down on a multi-cavity support clay base. The Support clay base will have synthetic properties, pressing the lure models to have way down will create an indention.

The dented part is where the plastic injection molding will happen. Clean the edges of the synthetic clay base and make some additions to the sides.

The latches are equally important as the molding area. The secure latches will ensure that the mold does not overflow or leak. Create small indentions for the latches as well. Once you clean and perfect the mold, pour the molding resin on the top. The molding resin will instantly fix the clay where it was.

Most of the work is done by the time you get to the injection molding part. The cavity is the basis for injection molding, you can create hundreds of molds every day once you have the perfect cavity. Likewise, a cavity with a structural defect will ruin any molds.

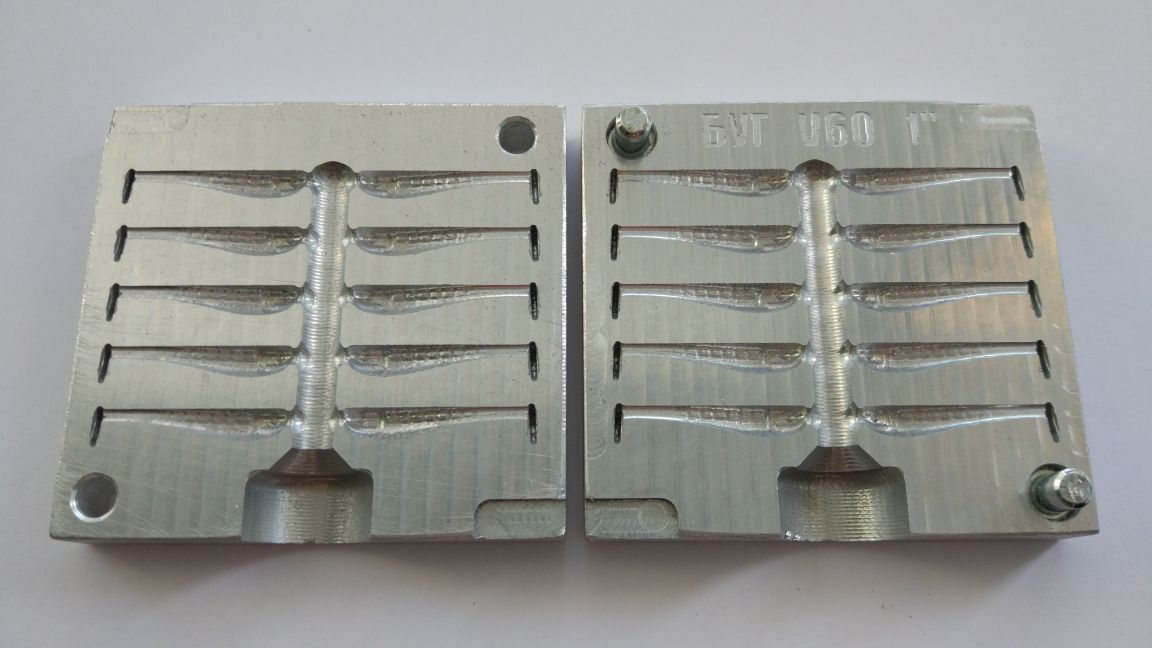

A slight defect can change the molded lure entirely. Measurements are very important while creating the plastic injection molds. Begin the injection molding process by securing two halves of the cavities in equal size. Both of the halves should have the same measurement and lock with each other in perfect unison.

Remember to leave space for the injection molding material to enter. The injection mold will exist in a semi-liquid form. The liquid resin will have a thick consistency and heated silicone will flow in molten form. The molten form will easily inject through the open area on the side of the cavity.

Once you fill the cavity up to the rim, leave it to simmer. Leave the cavity inside the refrigerator or any cold area for the prescribed time. O not leave the cavities inside the cold are for the sake of making it stronger since that will only make the opening harder.

Removing the plastic molds from the cavities is the most satisfying part of this entire procedure. The silicone or plastic lure will easily detach from the cavity and have a solid structure.

If you think that the mold still has a softer or runny consistency, then there is no point in freezing it. You should check the consistency and levels of the liquid resin to ensure that it does not have any impurity. Sometimes the issue leads back to the resin quality instead of the cavity structure.

You can continue with the injection molding process frequently with the same cavity or even change the existing cavity with a little effort.

The fishing lure injection molding procedure has made the lives of local producers very easy. This cost-efficient method is a reliable way of getting authentic results.

The biggest investment in this process is time. Time and patience are very critical while making the molds and cavities. The cavity production is the basis for perfect molding. Create cavities with the least imperfections and highest quality results. The industrial injection molding process includes quality checks and further refinement for the end product.

However home-based injection molding does not require the same effort, especially when the lure completes its job. The silicone and plastic molds are safe for the environment and you can administer them for animal fishing without any fear.

For further information regarding injection fishing plastic molds, Contact us now.