The plastic injection molding machines can fall on the costlier size due to their size and productivity. To avoid paying a leg and an arm for it, you can use the alternate plastic injection molding machine DIY. Sometimes it is better doing invest in machines that you can make yourself.

plastic injection molding machine DIY is one such machine that produces the same results as a manufactured plastic molded machine. They are very useful and have a full range of productivity. Plus, using a plastic injection molding machine DIY is a way better option than getting a bigger version when the results are the same. Making use of DIYs is an intelligent and compact solution for many problems.

Even if you are an amateur, you can still develop a plastic injection molding machine DIY. You can easily construct a plastic injection molding machine by following some steps. It is a piece of small-scale equipment but with a great many benefits. Although you can make plastic parts at home easily, there are some other ways that can help in its creation.

The productivity of an injection molding machine is very high with a great amount of accuracy in precision. Although the construction and designing can get a bit tricky for a layman, following simple steps to the dot can help. It can be an amazing experience for the creator. A plastic injection molding machine can help you in making different variations of molds of plastic.

They can vary in color, size, design, and much more. Once you make a DIY plastic injection molding machine you are good to go. It is the right kind of equipment for making a plastic mold in abundance. Once installed, they can work for many years without causing any trouble and raising any maintenance issues.

You can create things out of plastic using different ways. One method is to use the raw material directly, cut it and get the desired shape. On the other hand, you can make plastic objects by mixing molten resins with hardeners in the shape of the mold. Moreover, vacuum forming is ideal for making plastic objects out of thin plastic sheets.

Another way is to make a 3D printing machine for making plastic objects but this falls on the costlier side. Apart from this, it can take a lot of hard work and time to produce. Out of all these methods, the best and objective way to make the plastic thing is by using a DIY plastic injection molding machine.

It is by far the most appropriate way of developing plastic objects without a hassle. They make use of thermoplastics for making the objects. Additionally, it is a feasible choice for making larger quantities of plastic parts by replicating again and again. You can even use recyclable plastics for making the desired molds.

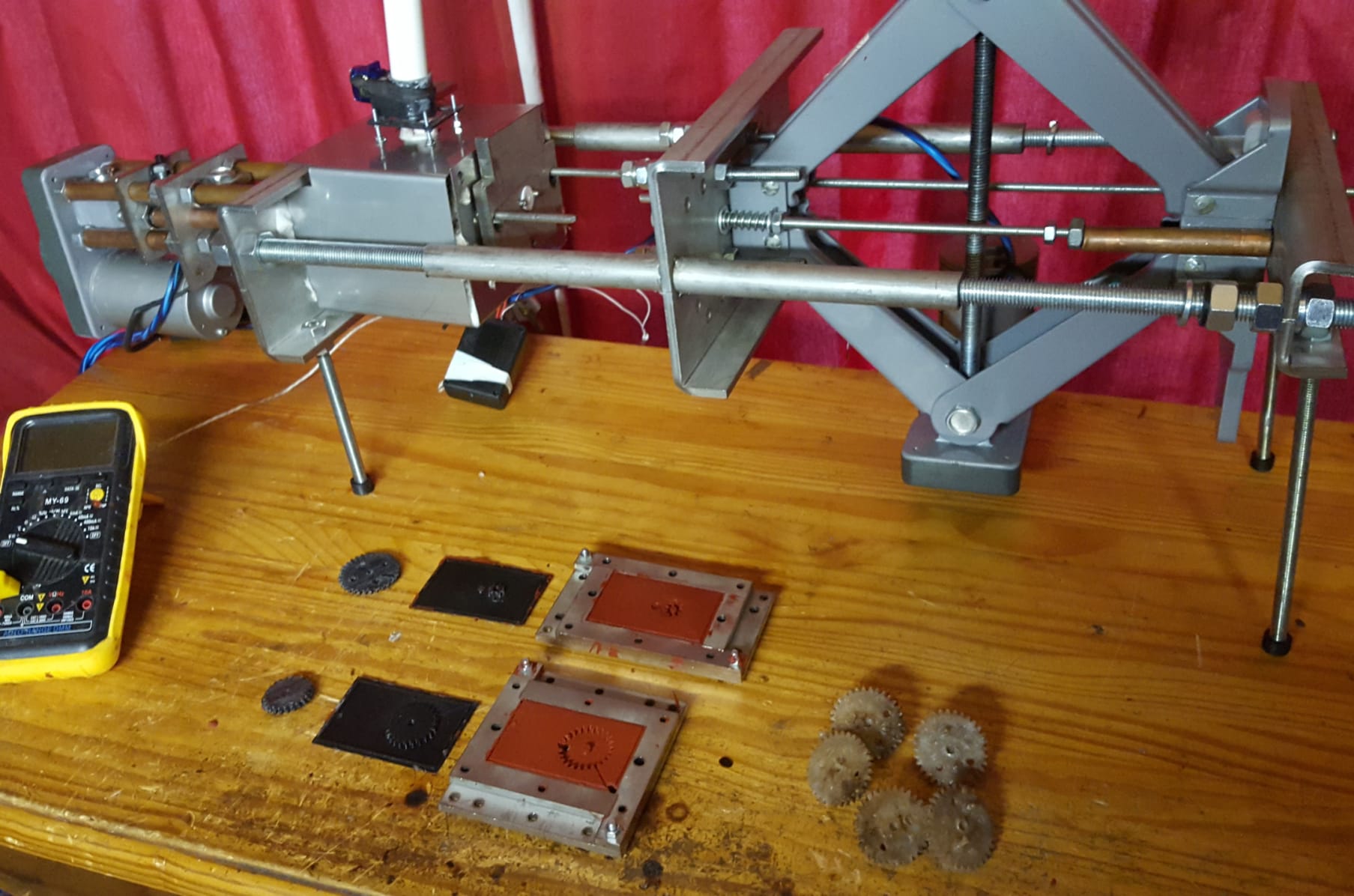

Building an injection molding machine is quite simple if you pay attention to details. Roughly, the project may cost around 100 to 200 dollars depending on the availability and the cost of raw materials. The basic element required in making an at-home plastic injection molding machine is metal. It is the basic element that makes up the whole machine.

You can easily find leftover metal at your home but in case you do not have it you can easily locate it at an iron dealers’ place or a hardware store.

The prerequisite for making a DYI plastic injection machine is to have the basic skills one needs for working with metals. Some tools that you may encounter while making a DYI project of the plastic injection molding machine are a milling drill, lather, a welder, a saw, horizontal bands a reamer, and a few taps.

Most of the time, you may require to use a drill press and a variation of other tools. For assembling the whole equipment you might need screws and drivers, and even a welder for welding some important parts. Although you can assemble the whole equipment yourself, it will be easier to hire a welder for your welding requirements.

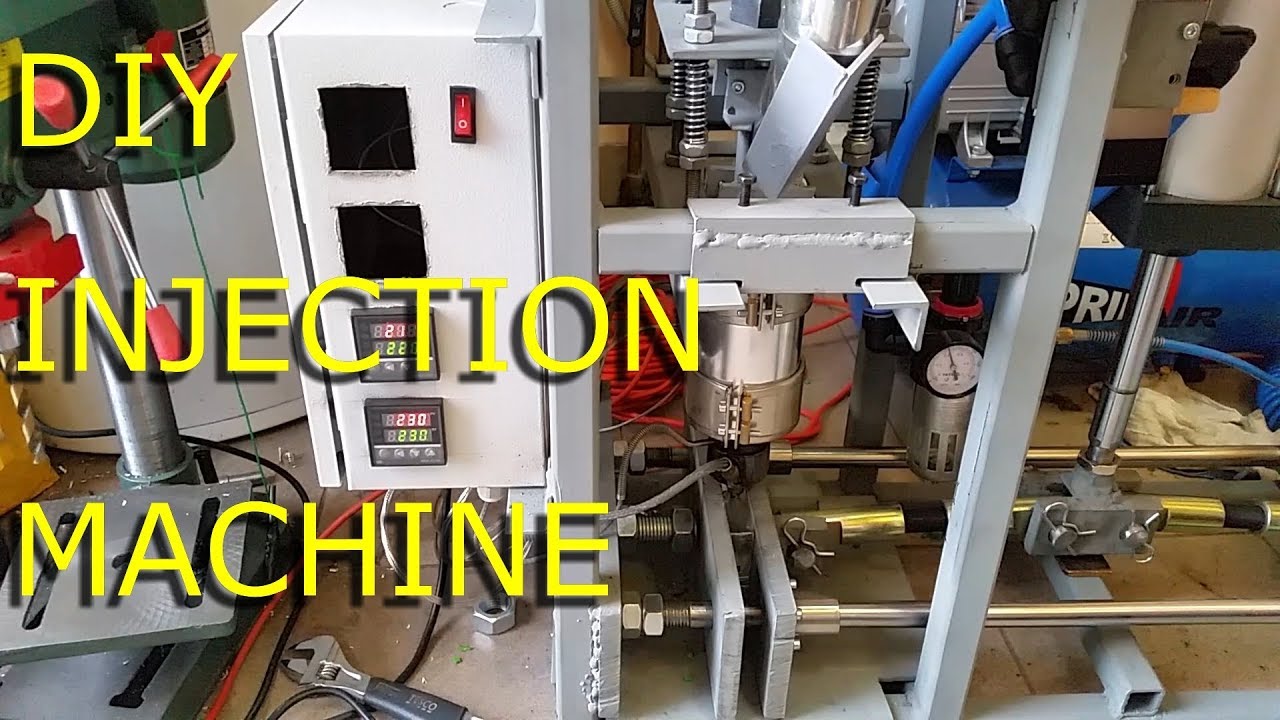

There are many instructions on the net for making a DIY plastic injection molding machine. You can even make your own improvement and implement them to make a newer and better version for yourself that suits your specifications. First of all, you may need cold-rolled steel that can act as an input in the heating block.

Here is where the plastic gets heat up so that you can inject it into the mold. Getting a wider heating block can allow you to add a couple of more cartridges to speed up the heating.

It is important is to make the equipment at a very precise angle on a flat iron surface. You can hold the whole assembly with the help of bolts and nuts but most importantly you need to get some parts welded for a better and stronger grip.

Choosing either way totally depends on you. When using nuts and bolts you need to make a lot of drills in the structure. Rather than doing a lot of drilling work, welding can save you a lot of time and maintenance in the future.

With the pivotal supplication, the injection lever hinges on a steel rod. You can mount the structure by drilling bigger holes in the casing. This can turn the steel bushing on the lathe to sustain the shaft. It keeps the lever centrally placed on the injection.

Moreover, you can use Allen head screws for mounting the heating and guiding block to the structure. The reason to use them is that they are much stronger and are poor conductors of heat hence, a better choice.

Another important factor while making a plastic injection machine at home is to control the temperatures. In conventional machines, you can easily time and look over the changing temperatures by using a thermostat.

In a DIY using a digital temperature controller is very important. Although it is an expensive choice, the readings will be accurate and easily readable. You can house the digital temperature controller separately so that the heat has no impact on it physically.

Once constructed, it is easy to use the machine. Before making a final design, you need to make a test run by using plastic pellets. Put these pellets in the controller that has a temperature set at 380 degrees. When it reaches the desired temperature, the pellets melt.

The melted plastic goes into the injection nozzle. When the injection plunges, it empties itself into the mold. Wait for the mold to cool down and then take the mold out. Now, your mold is ready.

Making a DIY plastic injection molding project at home is a great way of making plastic objects with ease. The injection molding machine can aid in many household projects and personal needs for making plastic tools. Rather than investing in a bigger and heavier version, make one at home and save money and time. It has a great reusability percentage with efficient results. Therefore, making it yourself can be very beneficial.

For More Information, Contact Us Today!