DIY Method to Make Plastic Bait Molds at Home

Today on sale there is a huge variety of all kinds of silicone lures and plastic bait molds. The popularity of such baits among anglers is increasing, and this is not surprising, because they show good results in fishing.

Fishermen are savvy people and have learned not only to repair broken silicone tips, but also to make them on their own, thereby saving the family budget. Among other things, with homemade manufacturing, you can seriously replenish the angler's assortment. To learn how to make silicone baits on your own, you need to know some features and secrets.

What are the benefits of homemade plastic bait molds?

Having learned how to make silicone tips on their own, each angler discovers a number of advantages and benefits:

- Every fisherman can make exactly those silicone tips that, in his opinion, are most effective when fishing for one or another fish;

- The angler can determine the shapes and sizes of homemade silicone baits by himself, because quite often there are situations when the silicone nozzles needed in size and shape are not in the store;

- The angler himself can make silicone baits of the colors he needs;

- Among other things, you can independently make silicone baits with a wide variety of aromas and tastes;

- The angler saves his money;

- If desired, the angler can put the production of homemade silicone baits on the stream, and make good money on this.

Repair of silicone plastic bait molds

When fishing with plastic bait molds, it often happens that they become damaged. Fishermen carry out the process of repairing such baits on their own, in several ways.

If the breakdown needs to be fixed right on the fishing trip, then the fishermen use ordinary matches or a lighter, they simply heat two parts of the broken silicone bait, and then press them together and hold them until they cool completely. With such a repair, it is very important not to overdo it and not overheat the silicone.

In some cases, anglers use glue, but at the same time the gluing site becomes much less elastic, and this state of affairs has a very bad effect on the parameters of the game of the repaired silicone bait.

If you repair silicone at home, this is possible with a soldering iron, thus, it is possible to achieve better heating of the joint, among other things, and you can correct the shape of the silicone nozzle that has repaired.

What will be needed to make your own silicone bait?

In order to establish the production of plastic bait molds on his own, the angler should stock up on the following components:

- The actual silicone itself

- You need gypsum

- Containers for gypsum

- Scales

- You should also prepare soap, preferably liquid in nature

- Syringe

- Dies for the casting process

- Dyes necessary for the angler

- Samples

How and where to get the silicone itself?

The easiest way to replenish stocks of silicone for casting silicone baits is to simply remit existing and completely unusable silicone tips. You can remit such silicone on a gas stove, in a water bath, or in a microwave oven.

You can use the purchase of silicone to make silicone baking dishes and other products, but in this case the forms themselves are tough, but they will last a very long time.

How to properly melt plastic bait molds?

To make silicone lures on his own, the angler should know that when excessively heated, silicone loses its characteristics. The best way to melt silicone for fishing lures is a microwave. It is in it that you can set the required melting temperature, which can also be found on the Internet.

You can also use a water bath on a gas stove, but this method is more laborious and requires special care from the manufacturer. Among other things, when heating, you should add fat, salt, various attractants and similar enhancers of taste and aroma.

Molds for casting silicone baits

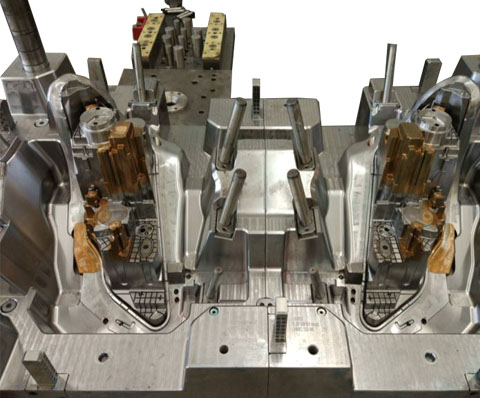

The process of casting plastic bait molds will not be possible without molds. Moreover, the forms consist of gypsum or plexiglass. Plexiglass molds are very difficult to make at home, but plaster molds are quite simple to make. Moreover, the matrices are either one-sided or two-sided.

One-sided shapes are most suitable for those silicone lures that do not have any complex shapes. To begin with, a body has to assemble, into which the plaster mold is to pour, after pouring the plaster, the sample immerses in it, while pre-lubricating it for easier pulling out.

Casting silicone baits

Lures such as vibro tails and many others are best cast using double-sided molds. At the same time, the manufacture of such matrices is practically identical to the manufacture of forms of a one-sided nature, but the sample has fill in only half. Double-sided molds are most suitable for casting silicone lures with complex shapes.

When making a matrix, remember that you need to leave special grooves, where silicone will subsequently be poured. It is best to fill the silicone with a syringe. You can make a silicone bait of two colors, but then you will need to stock up on two syringes.

To independently make different silicone plastic bait molds with your own hands, you must first make matrices for each type of such baits. After pouring the silicone into the mold and letting it cool, place the silicone tip in cold water to give it more elasticity. Then all that remains is to attach hooks to such homemade silicone baits, and the bait is ready for fishing.

Soft baits for every taste and color

There are many silicone baits available. They differ in many aspects - not only in a different shape, which affects the nature of the vibrations. Color and attractant are equally important - they contribute to the emergence of an irresistible desire in predatory fish to attack the bait.

Let's talk about the last two characteristics in more detail.

Colors

Classic white and yellow

The two traditional colors in which the first silicone baits painted are white and yellow. They have high contrast and are easy to make from one material. The lures of these flowers attract the attention of many predatory fish and are indispensable when used in troubled waters.

Red head

Some white soft plastic bait molds have a red head. Red imitates blood and attracts the attention of predatory fish. Fishing enthusiasts nicknamed them "Marlboro".

Natural color

These lures are characterized by the imitation of the color and color of certain fish. Most often it is roach and, in particular, perch, whose striped color is taken as the basis for many colors.

Glitter is used to imitate the special sheen of roach scales and bleak.

Fluorescent

Bright colors have become available in recent years. The use of orange, acid green, and pink can go a long way towards attracting predatory fish or when fishing in deep waters and muddy waters.

Why Automation of Plastic Molding is Important?

6 Benefits That Would Make You Want to Automate Your Plastic Molding Process Today!

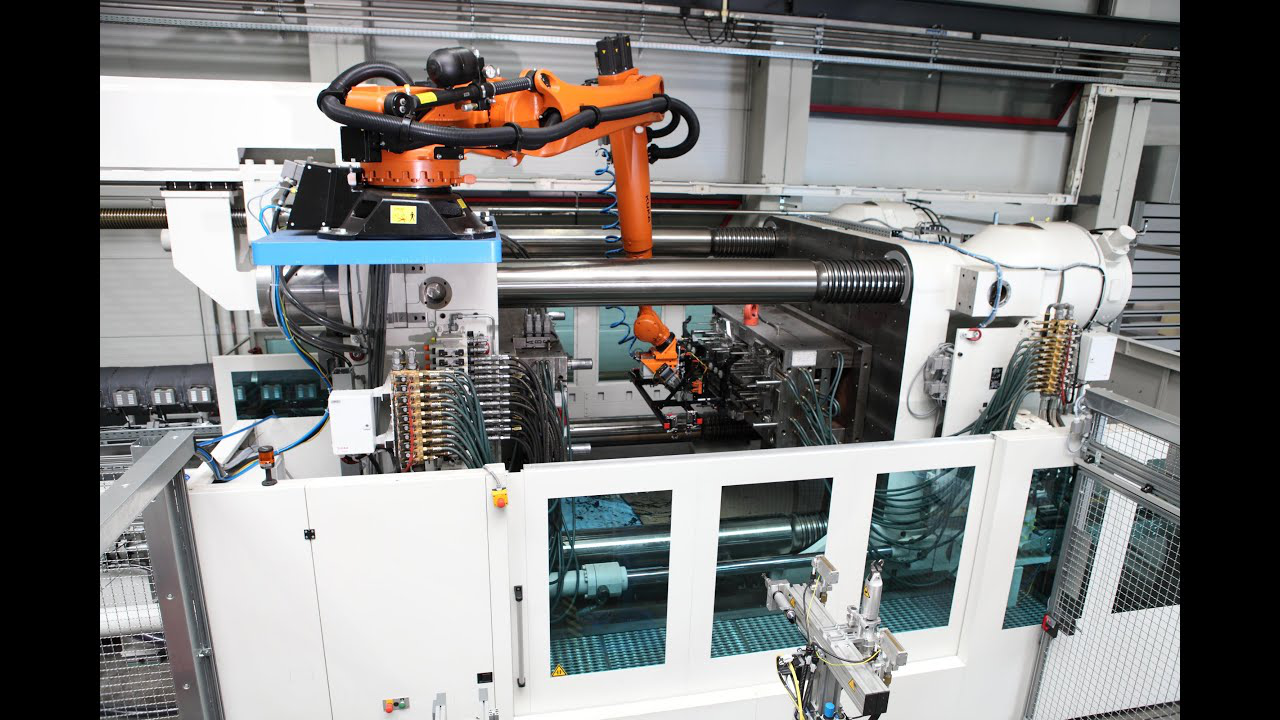

Automation in Plastic molding is experiencing a rising trend. Automated plastic molding machines made up 32% of all the machines sold in 2019, which has risen from 18% in 2010. Many ambitious molders opt for automated plastic-molding machines for the efficiency that the robots confer upon this process.

What is Plastic Molding?

If you are here looking for benefits of automation in plastic molding, chances are you already know what plastic-molding is. But still, let us brush up your knowledge a bit, and then we'll get to the pros in a moment.

Plastic moulding is a process of converting molten plastics into well-defined shapes and sizes. The injection molding machine melts granular plastics first. And then, it injects the molten polymer into a mold of any shape and size.

After being injected into the mold, the machine applies pressure to the molten plastic and cools. This way, the plastic solidifies and takes the shape of the cavity inside the mold. The mold then opens up, drops the plastic piece, and closes for the next 'shot,' and completes one cycle of the process.

A typical production cycle can take anywhere from 2 seconds to up to 120 seconds to complete.

What is Automation in Plastic Molding?

Automation of a process translates into the integration of innovative technology and smart robotics into any process. An automated process offers increased productivity, capacity, and efficiency compared to a non-automated, fully manual process.

The world is getting more involved in developing ultra-modern technology. People want technology to aid humans in every field and reap smart and efficient robots' benefits. The injection molding industry keeps up with the fast-paced world and takes immense interest in the automation of their processes.

Automation of the plastic moulding process gives the molders an edge over their competitors who are yet to integrate automation with their process. Now, to efficiently compete with their 'automated' peers, more and more molders are handing their processes over to the robots.

How is Automation Enhancing the Plastic Molding Process?

Automation is effectively augmenting the plastic-molding process by decreasing cycle times and ensuring consistency in product quality. Here are just a few of the many advantages that justify why plastic moulding automation is imperative in today's world.

1. Increases Productivity

Employing robots to perform specific tasks in your injection molding process will lead to increased productivity. Unlike humans, robots never sleep. They never take breaks. Moreover, they don't need to go home after their shift is over. Hence, an automized plastic-molding process can stay in operation throughout the day, seven days a week.

Therefore, by automizing the molding process, you can keep manufacturing and selling products without frequent breaks and enjoy increased revenue.

2. Increases Production Capacity

With increased productivity comes increased production capacity. Automated machines are capable of producing plastic-molded parts at a much higher rate than manual machines can. The increase in production rate is because automated machines work faster, without a pause. Thus, they are often capable of producing thousands of perfectly molded plastic pieces in just one day!

3. Ensures Consistency in Product Quality and Specifications

Humans tend to make mistakes. It is normal. But a mistake is not just a mistake in the plastic moulding industry. It is a loss—a loss of time, effort, and of course, money. In manual molding processes, chances of the product specifications deviating from customer-defined parameters are high, which leads to losses in terms of lead time and raw material.

However, once programmed appropriately, machines can roll out plastic parts in every cycle that match exactly with the specifications fed to the machine—thus adding consistency to the molding process's throughput.

4. Automation Minimizes Cost

The common idea associated with plastic moulding automation is that it is bound to cost you an arm and a leg to get robots to do the tasks that human workers are already doing.

However, contrary to this belief, integrating automated machines in your process saves you a lot of money. How? Firstly, a single machine takes the place of multiple workers, which means you save on the cost that you may spend on these workers' salaries and other incentives.

Moreover, an automated plastic molding process produces fewer defective parts, which means you save money on the raw material. Furthermore, since automizing optimizes the entire process, this means robots will yield a significant return on investment very quickly.

5. Optimizes the Process.

Automating your plastic molding process is a sure-fire way to optimize the entire process. Automated plastic moulding machines produce high-quality parts in every cycle, yielding fewer plastic parts to discard. Consistent-quality production saves a lot of raw material that would've otherwise been wasted if the produced part was defected and rejected.

Moreover, automizing the plastic moulding process saves up a lot of labor as machines clean any leftover plastic that tends to solidify in the mold. They also load molded plastic parts on the conveyers. Thus, they eliminate the need for humans to do such primitive tasks and allow you to assign your human workforce tasks out of the machines' performance scope.

6. Lowers the Risk of Workplace Injuries

An industry such as the plastic molding industry that involves a lot of heat in the form of molten plastic and heated plastic parts runs a high risk of worker injury.

Moreover, the plastic molding process requires repetitive tasks such as removing molded-plastic parts and loading them on a conveyor. Then packing them and preparing them for shipping. All of these tasks are not only tedious but monotonous and excruciatingly exhaustive. Thus, they may lead to elevated-stress injuries among the workers.

Therefore, by employing automated machines to do all the highly repetitive tasks, you can save your workers from work-related injuries and utilize their capabilities in a more productive and less physically exhausting area, such as operating the machines or programming the robots.

Final Thought

Most people often criticize robots and automated machines for stealing human jobs. However, the reality lies at the opposite end of this spectrum. An automated plastic moulding process does not replace humans with robots, but they create better higher-paying jobs.

These robots control the potentially harmful aspects of the processes. And allow humans to control and monitor the process while staying far from their life-threatening aspects.

Moreover, they prevent exhaustion and stress injuries among workers by performing repetitive tasks that are the trademark of the plastic moulding industry efficiently without getting tired.

Thus, the automation of plastic moulding has innumerable virtues not only for the plastic molding owners but for the workers as well. Automated machines reduce human downtime, lead time, cycle time and increase profits, all the while ensuring proper health and safety of the workers

The gross profit margin of kechuang board companies exceeds 50%, and the pharmaceutical industry ranks first

China Net Finance Daily, May 29 (Reporter Guo Medicine, Intern, Zhu Zhengxue) The establishment of the Kechuang Board has brought more opportunities for a display to many prominent R&D kechuang board enterprises. According to the iFinD statistics of Flush Huan, as of May 28, 105 companies have been listed on the kechuang Board. The average gross profit margins of these companies in 2017-2019 were 51.77%, 52.63%, and 53.49%, respectively. The trend is that competitiveness continues to increase, and in 2019, more than 100 companies have positive returns on net assets.

Median gross margin exceeds 50%

Gross profit margin is one of the important indicators to measure product competitiveness and profitability. In 2019, the average gross profit margin of 105 listed companies of kechuang board companies was 53.49%, and the median gross profit margin reached 50.32%, which was also an increase from 2018. The gross profit margin of all companies exceeds 10%, and the interest rate of 39 companies is above 60%, accounting for 37.14%.

Among them, Baolan ranked first with a gross profit margin of 96.46%, and Microchip Biotech ranked second with a gross profit margin of 95.81%. In addition, the gross profit margins of 52 companies such as Amethyst Storage, Ruichuang Weina, and Platinum are between 30%-60%. It is worth noting that the 55 companies of Kechuang Board Company Bannan New Pharma, and Pumen Technology have improved their gross profit margin in 2019 compared with 2018, and 33 of them have increased their gross profit margins from 2017 to 2019.

According to Shenwan's first-level classification, since the establishment of the kechuang board, there are 105 listed companies, mainly concentrated in 19 sub-industries, such as non-metallic minerals, pharmaceuticals, and special equipment manufacturing, including pharmaceuticals. Compared with 2018, the average gross profit margin of 12 industries including the technology service industry and food manufacturing industry has increased in 2019.

Four of the top 10 companies in the gross profit margin of Kechuang Board are concentrated in the pharmaceutical manufacturing industry, software, and information technology services, and there are also special equipment manufacturing industries. The top 10 companies with a net return on equity are mainly concentrated in the pharmaceutical manufacturing industry, followed by the software and information technology services industry and the computer, communications, and other electronic equipment manufacturing industries.

Gross margins generally increase

In 2019, among the 19 sub-sectors of the Science and Technology Innovation Board, the pharmaceutical manufacturing industry ranked first in the industry with an average gross profit margin of 72.12%, and it has increased from 2018. Multiple policy support and planning.

Specifically, in addition to Zejing Pharmaceuticals not yet profitable, the average gross profit margin of 13 other companies in the pharmaceutical manufacturing industry can reach 77.66%, and the gross profit margins of 10 companies including Tebao Biological, Huaxi Biological, Haohai Shengke, and Borui Pharmaceutical All are concentrated in more than 70%, of which the core gross profit rate of Weixin is the highest, reaching 95.81%, which is the leading enterprise in the industry.

As shown, the average gross profit margin of the software and information technology services industry will be the second in the industry in 2019 and 2018, and 2019 will increase compared to 2018. In 2017, the "Software and Information Technology Services" Industry Development Plan (2016-2020) released by the Ministry of Industry and Information Technology provided guidance and financial support for the national software and information technology services industry, which is of great significance for promoting the development of the industry.

As of now, there are 19 listed companies in the technology board software and information technology service industries. The average gross profit margin of the industry in 2019 reached 66.04%. The gross profit margins of 11 companies such as Hongruan, Kingsoft Office, and Shanshiwangke all exceeded 60%. Among them, Baolan's gross profit margin was 96.46%.

In addition, the special equipment manufacturing industry has also achieved the average gross profit margin for two consecutive years and ranks in the forefront of the industry. Among the 22 companies listed in this industry, 12 gross profit margins are mainly concentrated in the range of 40%-70%, accounting for 54.55%. The gross profit margin of the other five companies was higher than 70%, accounting for 22.73%. Huafeng Measurement & Control, Xinmai Medical, Ruisong Technology, and other 11 companies have gross margins in 2019 exceeding 2018, and gross profit margins are in the improvement stage.

Guangdong launches action plan to build a high-end equipment manufacturing base

Guangdong is a major manufacturing province with a complete range of industries. However, in the process of industrial transformation and upgrading, "bottleneck" issues such as core technologies remain prominent. Recently, the Guangdong Provincial Department of Industry and Information Technology released the "Guangdong Province Development Plan for Cultivating High-end Equipment Manufacturing Industry" (2021-2025, draft for comments) recommending that it be transformed into manufacturing high-end CNC machine tools, aerospace equipment, satellites, and their applications. Railway transportation equipment, marine engineering equipment, and other important bases for manufacturing high-end equipment nationwide.

The solicitation draft proposes that by 2025, Guangdong will establish multiple national and provincial innovation centers and laboratories to promote breakthroughs in key technologies and key components in key areas. The annual income of the high-end equipment manufacturing industry will increase by more than 6%. Cultivate a group of industry leaders with international influence and independent brand value.

The consultation draft shows that Guangdong has now cultivated a number of equipment manufacturing enterprises and emerging enterprises, and its economic growth has been ranked first in the country for 30 years. But at the same time, the development of the high-end equipment manufacturing industry also faces many challenges: including the key core technology is constrained by people, independent research and development and innovation capabilities are insufficient, the problem of "jam neck" is still prominent; the foundation of heavy equipment is relatively weak, the industrial supporting system is not perfect, and high-end CNC systems, High-reliability electric spindles, cutting tools and other key components depend on the existing supporting equipment, and the large-scale overall machine enterprises are seriously insufficient in their relevance and supporting capacity to small and medium-sized enterprises.

The consultation draft pointed out that Guangdong's high-end equipment manufacturing industry is in a critical period of transforming from element-driven to innovation-driven to digital, networked, and intelligently upgraded. It will pass five key tasks and five key projects. Complete the development goal of maximizing high-end equipment manufacturing in 2021-2025.

Tang Yue, Deputy to the National People's Congress and Chairman of Chutian Technology: Promoting the R&D of Biopharmaceutical Equipment to Meet the "Era of Pharmaceutical Industry 4.0

⊙Reporter Xia Zihang ○ Editor Xu Rui

Just as the National People's Congress deputy, Chu Tian Technology Chairman Tang Yue foresaw a few years ago, where the pharmaceutical industry is fully entering the "pharmaceutical industry 4.0 era." In his view, it is very important to deepen the public health reform of the disease control system, establish a modern disease control management system, and accelerate the development of biopharmaceutical equipment.

Develop pharmaceutical equipment to help prevent and control COVID-19

"The new coronavirus, which has a high infection rate, a long incubation period, and multiple transmission routes, poses a huge challenge to the world's pharmaceutical industry." Tang Yue said.

At this year's two national conferences, Tang Yue put forward "suggestions on accelerating the development of biopharmaceutical equipment and improving local disease prevention and control capabilities." "Biopharmaceuticals are an important part of the national economy and have a closer relationship with people's livelihood. The main popular figure Tang Yue said that at present, the gap between the level of domestic biotechnology and biopharmaceutical core equipment is far from the world's advanced level.

In response to this problem, Tang Yue suggested that the state should introduce supporting policies to encourage the development of biopharmaceutical equipment, focusing on enhancing the emergency production capacity of epidemic prevention and control products; further promoting traditional Chinese medicine, accelerating the research level of Chinese medicine preparation equipment, and promoting Chinese medicine preparation equipment Quickly realize automation, digitalization, and intelligent upgrades; at the same time, encourage school-enterprise cooperation to achieve integrated development of production, education, and research, make full use of talents from universities, research institutes, R&D, technological advantages, and enterprise platforms and market advantages, and actively promote R&D and production, Close cooperation in sales.

The arrival of "the era of pharmaceutical industry 4.0"

A few years ago, Tang Yue said to the Shanghai Securities Journal reporter that in the future, the medical equipment industry will usher in a continuous huge dividend in the world, that is, "pharmaceutical industry 4.0" and the upgrading of pharmaceutical intelligent manufacturing. The direction of development will be obvious after 5 years, and there will be changes in the outline after 10 years. In Tang Yue's view, "Pharmaceutical Industry 4.0" can greatly reduce the hidden dangers of medical safety.

According to reports, pharmaceutical intelligent manufacturing and "Pharmaceutical Industry 4.0" can realize real-time, online, full-range, all-round automatic monitoring of pharmaceutical manufacturing and circulation consumption, and automatically generate data (and cannot be tampered with), automatically read data, Automatically store data to the cloud, zero delays, no dead ends, no blind spots. According to the authorization of the law, regulatory authorities, drug producers, and consumers can consult and retrieve relevant data.

Tang Yue believes that in the future, high-end pharmaceutical equipment, "pharmaceutical industry 4.0" and intelligent manufacturing will be regarded as "rigid demand" for pharmaceutical factories. Based on long-term foresight, Chutian Technology has successfully developed some intelligent pharmaceutical production robots and related production lines using automation and information technology and is transforming into an EPC service provider that builds a "pharmaceutical industry 4.0" smart factory overall solution.

The 2019 annual report shows that Chutian Technology's industrial layout has begun to show its advantages. The traditional advantage of Chutian Technology lies in the liquid pharmaceutical equipment, and its production and sales are at the forefront of the industry; Chutian Huatong, a wholly-owned subsidiary, is a professional research and development of pure steam generator, multi-effect distilled water machine, purified water preparation system, and other products. Manufactured pharmaceutical equipment manufacturing enterprise; Military Pharmaceutical Engineering Design Service of Sichuan Pharmaceutical Design Institute, a wholly-owned subsidiary; Chutian Robot, the holding subsidiary's main products are medical and medical robots; in 2019, Chutian Technology has added an intelligent Chinese medicine machinery product line.

Chutian Technology recently stated on the interactive platform that Sichuan Pharmaceutical Design Institute, a wholly-owned subsidiary of the company, has the design and construction capabilities of the P3 Biosafety Laboratory. During the epidemic prevention and control period, Sichuan Medical Design Institute undertook the design of the high-level biosecurity laboratory (P3) of the Eighth People's Hospital of Guangzhou City, which was highly recognized by hospital experts.

Currently, Chutian Technology is planning a follow-up merger and acquisition of ROMACO. ROMACO is currently the seventh-largest medical equipment company in the world and a senior solid preparation packaging manufacturer. Its products have entered more than 100 countries and regions in the world.

In the Internet age, how does the medical "couple shop" live?

"At the time I was being consulted and my wife was dispensing medicine. When I am the busiest, I will call my cousin to take care of them. Many people in the village come here to see a doctor. "

Speaking of which, Dr. Li's hand in the clinic shook slightly. But the white coat and hair still maintain the rigor of the past, meticulous.

The plaque after the unified reconstruction of the streets has faded, and the outer walls are covered with medical notices and aftertastes of Chinese medicine and disinfection water. All the decorations are the same as the older Dr. Li and his wife: traditional, stubborn, and deadly.

This is a typical small self-employed clinic with a couple of "1 doctor + 1 pharmacist", which is what most medical "couple shops" look like.

"Now that the nurse has resigned, you must clean and disinfect yourself. You can get full every month." Dr. Li took off his glasses, drank strong tea, and took a long breath.

In the half-day of the interview, there was indeed only one guest in the pharmacy in front of us to buy Band-Aid. In addition, most of the time, Dr. Li and his wife Jiang Yaoji are studying how to use the latest online purchase software. As far as the two old doctors are concerned, the learning process is not simple. Finally, they still had to embarrassingly choose to call the service staff of the original pharmaceutical company.

However, once started, the sales staff will follow the software introduction and "enthusiastically" recommend Dr. Li to participate in the clinic upgrade project, and encourage: "Several clinics in your area have joined, and your traditional clinic is outdated. No, It doesn’t matter, we can come over to help you personally."

In response, Dr. Li refused without thinking. He hung up the phone, turned back to "the theory of relativity intelligence," and asked: "I don't understand. In the hospital, our old doctors are also somewhat famous, and the registration fee is a few yuan more expensive. Now that the Internet is coming, should we damn it? "

"Dare you dare to see a doctor on the Internet?"

Before opening his own clinic, Dr. Li was an orthodox medical student of that era and the successor dean of a township hospital.

“After I took office in 2005, the hospital was sold. I couldn’t do anything except seeing a doctor, so I rented a house and opened a clinic. I was in charge of injections, and my wife became a pharmacist. Whenever It is very busy at noon, often eating cold meals or not eating at all. There is no way, once the patient enters the door, we must receive him immediately."

But with this desperate hard work and excellent medical skills, this small clinic of only a few tens of square meters became famous locally in only one year. In 2010, Dr. Li simply bought a facade and expanded the clinic on "his own place".

"He looks fierce. In fact, he has always been an idealist. Those who do not need injections only need oral medicine. In the past SARS, this medicine was very expensive. If you give him more money, he still gets angry. There are six to seven clinics on this street, familiar (people) come often (Dr. Li's clinic), and people who often come from nearby cities..." Li's neighbor quietly asked "Intelligent Relativity".

However, when a company is doing too well, the capital that exudes "fishy smell" will always squeeze into this field and start to compete. In the eyes of capitalists, even life-saving medical treatment is nothing but "business."

Data from the China Health Statistics Yearbook show that between 2010 and 2017, the number of clinics in non-public grassroots medical and health institutions increased from 173,434 to 211,572, an increase of about 22%. The proportion of the total number of institutions rose from 41% to 54%.

Also at that time, Dr. Li and his wife felt that the (clinic) became more and more difficult to do.

Especially in June 2015, "Several Policies and Measures for Promoting the Rapid Development of Social Medical Treatment" (hereinafter referred to as "Measures") was issued. The state proposed to insist on opening medical treatment and implemented "non-prohibited entry" for social capital After the gradual progress, the feeling becomes more obvious.

The "solution" divides qualified social medical institutions into the scope of medical insurance fixed points and implements the same policies as public medical institutions. This solves the medical insurance problem, and also allows the Internet operation model to explode rapidly after the capital officially enters the market, making medical "self-employed" even more difficult to chase.

Overcome the core technology of meltblown cloth to achieve multi-spec mass production

Since the outbreak of new pneumonia worldwide, meltblown fabrics have multiplied and become the core material of medical protective masks. In order to ensure that the Boomingshing medical production line of Changhong Technology's subsidiary needs to produce 3 million pieces of mask raw materials every day, and save procurement costs, and make full use of Changhong's powerful mold technology background technology, the group chairman Li Huanchang decided to establish on April 15, 2020. A technical team supporting the research and development of melt-blown fabrics to overcome the precision spinneret technology of melt-blown fabric molds and the production technology of high-temperature injection molding spray glue. The goal is to produce and sell core raw materials.

The first stage, to overcome the core technology of precision spinneret

This task of research and development and production of precision molds has been transferred to its subsidiary Shanghai Changmei Precision Moulds Ltd. On April 15, after receiving the task, Xu Yanping, the general manager of the company, personally selected the technical backbone to form a research and development team. It took only 3 days on April 18 to overcome the precise processing technology of the melter nozzle spinneret and complete the smooth assembly of the 600-hole nozzle module with high efficiency and high quality. Subsequent assembly of various specifications and models, such as 600-type aperture (0.15mm, 0.20mm, 0.25mm, 0.30mm), 1600-type aperture (0.20mm, 0.25mm, 0.30mm).

The second stage, to overcome the high-temperature injection molding production technology

In the coronavirus disease, time is life. On May 2, 2020, the melt-blown fabric production workshop began construction day and night at Changhong Technology's Shenzhen Pingshan Plant, and the equipment installation was completed con May 7 in only 6 days. Xu Yanping, general manager of the company, personally stationed on the front line of the workshop and worked hard with the process engineer to debug the day and night process. On May 8th, he overcame the production technology of high-temperature injection molding of melt-blown cloth. The best combination, 6 production lines to achieve smooth production. Meltblown cloth PFE99 (32L/min, 15pa/cm2), specifications (150, 175, 260), weight (0.22, 0.25, 0.30, 0.40), after testing and certification to achieve industry-leading excellent quality, daily capacity can be reached after capacity release 10 tons +, fully meet the self-production and sales demand of disposable medical masks, N95 mask raw material supply chain.

Changhong Technology is ingenious in fighting against epidemic disease, and we are all committed to the city. We have been working hard to provide high-quality products and services and work tirelessly for the cause of human health!

Shenzhen Changhong Technology Co., Ltd.

May 30, 2020

Announcement on donations to support the fight against the new coronavirus pneumonia epidemic

All members of the company and the board of directors guarantee that the content of information disclosure is true, accurate, and complete without false records, misleading statements, or major omissions.

1. Overview of donations

Shenzhen Changhong Technology Co., Ltd. (hereinafter referred to as "the company") has effectively fulfilled the social responsibilities of listed companies, helping to prevent and control pneumonia caused by new coronaviruses. While doing its own prevention and control work, on February 2, 2020, the company used its own funds to donate 1 million yuan to the epidemic areas in Hubei and other regions through the Shenzhen Red Cross.

According to the "Shenzhen Stock Exchange GEM Stock Listing Rules", "Articles of Association" and other relevant regulations, this donation does not constitute a connected transaction and does not need to be submitted to the company's board of directors and shareholders' general meeting for consideration. It does not constitute a major asset restructuring as prescribed by the China Securities Regulatory Commission's "Management Measures for Major Asset Restructuring of Listed Companies." And does not require approval from other relevant departments.

2. The impact of this donation on the company

The company's external donations are to support the fight against New Coronary Pneumonia and contribute to the prevention and control of New Coronavirus. It meets the requirements of the company's active commitment to social responsibility and is conducive to enhancing the company's social image. This time the external donation funds come from the company's own funds, and will not have a significant impact on the company's current and future operating performance, nor will it have a significant impact on the interests of investors.

Special announcement!

Board of Directors of Shenzhen Changhong Technology Co., Ltd.

February 3, 2020

Voluntary Announcement on New Coronary Pneumonia Related Products

All members of the company and the board of directors guarantee that the content of information disclosure is true, accurate, and complete without false records, misleading statements, or major omissions.

I. Overview

1. Faced with the prevention and control of pneumonia caused by new coronavirus infection, Liyin Precision is acting.

Liyin Precision Medical Products (Shanghai) Co., Ltd. (hereinafter referred to as "Liyin Precision") is a holding subsidiary of Shenzhen Changhong Technology Co., Ltd. (hereinafter referred to as "Changhong Technology" or "Company") and is a research and development company. High-tech enterprises that mainly produce and sell medical device products. Established R&D and innovation centers including central laboratories and test centers, etc., and gradually formed six series of products including specimen collection systems, human-assisted reproductive systems, POCT reagents, sample processing systems, genetic testing reagents and consumables, and laboratory consumables. The mainline of the emerging medical device industry base.

With the rapid spread of the new coronavirus pneumonia epidemic (2019-nCoV), which poses a huge threat to the life and health of the Chinese people, Liyin Precision immediately launched an emergency response mechanism for the epidemic, paying attention to the progress of the disease and organizing The company's R&D, production, quality, logistics, and other departments started construction ahead of schedule to fully prepare for the production of four epidemic-related products. According to the "Notice of the Shanghai Municipal People's Government on Delaying the Resumption of Enterprises and Development of Schools in this Municipality", Liyin Precision actively responded to the spirit and requirements of the national epidemic prevention work and began normal work on February 10, 2020. At that time, the company's internal work arrangements are as follows:

- For single-use virus sampling tubes, blood collection tubes for nucleic acid detection, biosafety centrifuges, and automatic vacuum blood collection tube sealing machines, priority is given to the production of four types of products related to the recent epidemic.

- In response to the epidemic situation in Hubei Province, the company will fully cooperate and coordinate various resources to give priority to the production and delivery of orders from customers in Hubei. The company and colleagues in Hubei overcame difficulties together and fought against the epidemic.

- At present, the company's sales department and marketing department staff have been working online at home, and our staff can be contacted on QQ, WeChat, and telephone.

2. Facing the prevention and control of pneumonia caused by new coronavirus infection, Boomingshing is taking action.

Shenzhen Boomingshing Medical Device Co., Ltd. (hereinafter referred to as "Boomingshing") is a wholly-owned subsidiary of Changhong Technology. It is mainly engaged in the design, development, and production of medical consumables and medical devices, medical tests, and basic equipment and appliances. Processing and sales, mainly for the global market to provide gene products full industry chain consumables, assisted reproductive consumables and reagents, life science laboratory consumables, IVD diagnostic consumables and reagents, special equipment manufacturing products and services.

In the fight against the new pneumonia epidemic of the new coronavirus in 2020, Boomingshing is currently mainly Shenzhen Huada Gene Co., Ltd. (hereinafter referred to as "Huada Gene"), Shenzhen Mindray Biomedical Electronics Co., Ltd. (hereinafter referred to as "Mindray Medical") ") and other customers to provide matching kits and consumable products.

The new coronavirus 2019-nCoV nucleic acid detection kit is a rapid detection kit based on RT-PCR technology and a detection kit based on metagenomic sequencing. Combining the above two detection methods, the 2019-nCoV virus detection can be covered faster and more comprehensively, and the mutations that may occur during the spread of the new coronavirus are monitored. In fact, the kit is the top priority for the diagnosis of new coronavirus. For the detection of the new coronavirus, the most important method at present is to detect whether there is the viral genetic material in humans (sputum, blood, alveolar lavage fluid), so as to confirm whether it is infected by the virus.

As a manufacturer of new coronavirus detection kit supporting products, Boomingshing urgently organized a 65-person team to rush production 24 hours a day and 24 hours after receiving the supply request of Huada Gene on January 30, 2020. The shifting work system, shouldering the mission of the enterprise, satisfies the needs of customers and realizes a daily output of about 28,500 pieces of new coronavirus detection kit supporting products. Boomingshing actively responded to the national epidemic prevention and control spirit and requirements and started construction on February 1, 2020, in advance, giving priority to the research and development and production of the following epidemic-related products.

- Related consumables using Huada gene DNBSEQ-T7 sequencing system and new coronavirus detection kit;

- Use the chemiluminescent reaction cup of Mindray Medical Biomedical Biochemical Testing;

- Blood collection tubes and free DNA tubes for blood testing;

- 96-well storage plate for gene sequencing.

This product is mainly used for diagnosis, sample collection, and sequencing in epidemic prevention work.

II. Introduce products related to new coronary pneumonia

1. A disposable virus sampling tube

The current new coronavirus is an RNA virus. After the samples are collected, incorrect storage or transportation may cause some nucleic acids to degrade and affect the test results. In addition, unactivated virus samples are likely to cause operator and indirect infection. For the laboratory, the safety level is high; and use existing nucleic acid detection kits, professional specimen collection tools should be used.

The single-use virus sampling tube is used for the collection and transportation of clinical influenza, new coronavirus, avian influenza (such as H7N9), hand-foot-mouth virus, measles, and other virus specimens, as well as mycoplasma, ureaplasma and chlamydia specimens. With the launch of new coronavirus detection reagents and general screening, the demand for single-use virus sampling tubes has increased significantly. In response to the production of products in short supply during the epidemic period, the company has increased its personnel into production during the holidays, and it can be supplied in large quantities one after another.

2. One-time blood collection tube for nucleic acid detection

Labtub® disposable blood collection tubes for nucleic acid detection (referred to as "nucleic acid detection tubes") are specially designed and manufactured for nucleic acid detection, mainly used in blood collection and supply institutions (blood stations, blood centers) and hospitals for venous blood samples for nucleic acid detection Collection, transportation, and storage, as well as pre-treatment of specimen analysis, to meet the clinical nucleic acid amplification test and clinical molecular diagnostic test methods to quickly prepare undiluted plasma specimens.

- It is produced under pure purification conditions, and the possible pollution is minimized during the production process, effectively reducing the impact of possible carry-over pollution on the experiment.

- The inner wall of the vacuum blood collection tube is treated with DEPC, the finished product is sterilized by Co60 irradiation, and the sterility guarantee level can reach 10-6, which can completely eliminate the effect of RNase on the experiment.

- The application of unique additive technology will not affect the activity of the Taq enzyme in the nucleic acid detection experiment, and can effectively eliminate the interference of the hemoglobin in the red blood cell on the nucleic acid detection experiment.

In this new coronary pneumonia, the company's nucleic acid test tube can ensure the accuracy of the blood nucleic acid test results of the new coronavirus. To support epidemic prevention, the company has stocked hundreds of thousands of products.

3. Biosafety centrifuge and automatic vacuum blood collection tube sealing machine

Transmission through the respiratory tract droplets is the main transmission route for 2019-nCoV, and may also be transmitted through contact and aerosol (aerosol). An aerosol is a dispersion system in which solid or liquid particles are suspended in an inverse gas, and the particle diameter is between 0.001 and 100 μm. Medical laboratory and other personnel mainly contact patients' blood, urine, feces, and other samples, which can produce an aerosol. It can effectively eliminate aerosol pollution and avoid the biological contamination of medical personnel and cross-contamination between specimens by aerosol during the uncapping of blood collection tubes.

a. Biosafety centrifuge

Product use: Vacuum blood collection tube (specimen) centrifugal uncap; ordinary specimen centrifugation.

Product advantages: It can prevent aerosol pollution; the speed and centrifuge time of the centrifuge can be set freely, and the centrifugal force can be directly converted and displayed.

b. Automatic vacuum blood collection tube sealing machine

The automatic sealing machine introduced by Liyin Precision for the vacuum storage of blood collection tubes after the analysis of specimens in medical laboratories makes the post-processing of specimens safer, more convenient and more convenient, and is an ideal choice for laboratory safety and quality control.

The product has the following characteristics:

Each sample is sealed independently, so blood samples will not cross-contaminate when stored in the refrigerator. Maintain the originality of the specimen to the greatest extent to ensure the safety of the specimen and the safety of the personnel; discard the previous ordinary cling film cover or manually prevent the sealing method, use automatic machine sealing and stoppering, and the rubber stopper is pressed by the robot. It is suitable for various instrument tube racks without manual sample transfer.

4. Gene storage board

The product has the following characteristics:

Suitable for storage of most polar organic solutions, acidic and alkaline solutions, and other laboratory solutions; suitable for biological fields, such as PCE, RIA, EIA, cell culture, DNA testing, etc.

5. One-time use of vacuum blood collection tube

Scope of application: For the collection, storage, transport, and pretreatment of venous blood samples in clinical laboratories.

III Company performance and risk tips

Since this new coronary pneumonia occurred, sales of the company's kits and other epidemic-related products have increased compared with the same period last year. It is estimated that the subsequent sales revenue will change according to the development of the epidemic. Specific financial data will be disclosed in the 2020 periodic report.

Special announcement!

Board of Directors of Shenzhen Changhong Technology Co., Ltd.

February 6, 2020

Announcement on the completion of the industrial and commercial change registration of wholly-owned subsidiaries

All members of the company and the board of directors guarantee that the content of information disclosure is true, accurate, and complete without false records, misleading statements, or major omissions.

Shenzhen Changhong Technology Co., Ltd. (hereinafter referred to as the "Company") received a notice from the wholly-owned subsidiary Shenzhen Boomingshing Medical Device Co., Ltd. (hereinafter referred to as "Boomingshing"), and actively responded to the call of the national and local governments to take effective actions To support the epidemic prevention of new coronaviruses, the company's business scope will be adjusted accordingly, and "production and management of masks and forehead guns" will be added.

At present, the registration procedures for industrial and commercial change (registration) have been completed and the "Business License" issued by the Shenzhen Municipal Market Supervision Administration has been obtained. The main information is as follows:

Unified Social Credit Code: 91440300552122647A

Company Name: Shenzhen Boomingshing Medical Device Co., Ltd.

Type: Limited liability company (wholly owned by the legal person)

Legal representative: Li Huanchang

Date of establishment: March 11, 2010

Address: Floor 1 to 3, No. 4 Plant, Fuxingda Industrial Park, East Lanzhu Road, Pingshan New District, Shenzhen

Business period: Sustainable operation

Business Scope: Class I (Class I) medical consumables and medical devices, Class II 6841 medical testing and the design and development, production, processing, and sales of basic equipment and appliances, production and operation of masks and forehead guns; digital product accessories, production, processing, and sale of plastic products; import and export of goods, import and export of technology (articles prohibited by laws and administrative regulations; articles restricted by laws and administrative regulations must be licensed before they can operate). Engaged in Class II medical testing and sales of basic equipment; Class II and Class III injection puncture instruments, medical polymer materials and products, medical hygiene materials, and dressings. "

Special announcement!

Board of Directors of Shenzhen Changhong Technology Co., Ltd.

February 19, 2020