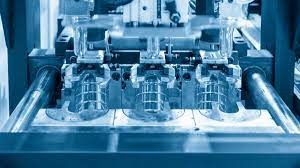

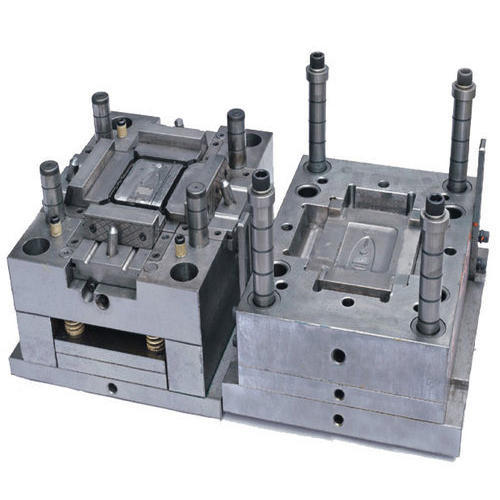

MULTI-CAVITY MOLDS NEED TO BE BALANCED TO GUARANTEE PARTS WITH THE SAME CHARACTERISTICS

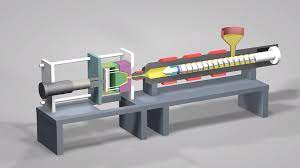

Custom plastic molding company provides a balanced mold. Generally, it happens with the same injection time and the same pressure in the cavity. The filling of the cavities must come in a uniform way. Moreover, the stages packing and retention will have the same effect on all the pieces.

A cavity fills less than another in the filling stage. When performing the holding phase, it will generate a greater pressure in the cavity and as a consequence a part with “dimensions greater” than the rest.

CONTROLLING THE PRESSURE WITHIN THE CAVITY

As a good process technician in custom plastic molding company you must make sure that the mold you are injecting meets a good balance. Moreover, this is easy to do through fill studies and verify the variation or standard deviation does not exceed the limits allowed.

If you detect a variation outside the limit, now the task is to discover the cause that originates it, which can be one of the following lists:

- Material below processing temperature.

- Poor homogeneity in the temperature of the melt.

- Moreover, Geometric difference in flow and gate channels.

- Differences in the installation of degassing zones clogged or poorly designed vents.

- Similarly, Bad design of the piece.

- Bad distributor design.

- In addition, temperature differences in mold cooling.

- Temperature differences in the hot runner and injection points.

- Furthermore, injection speeds not adequate.

- Rheological flow of plastic in distribution channels.

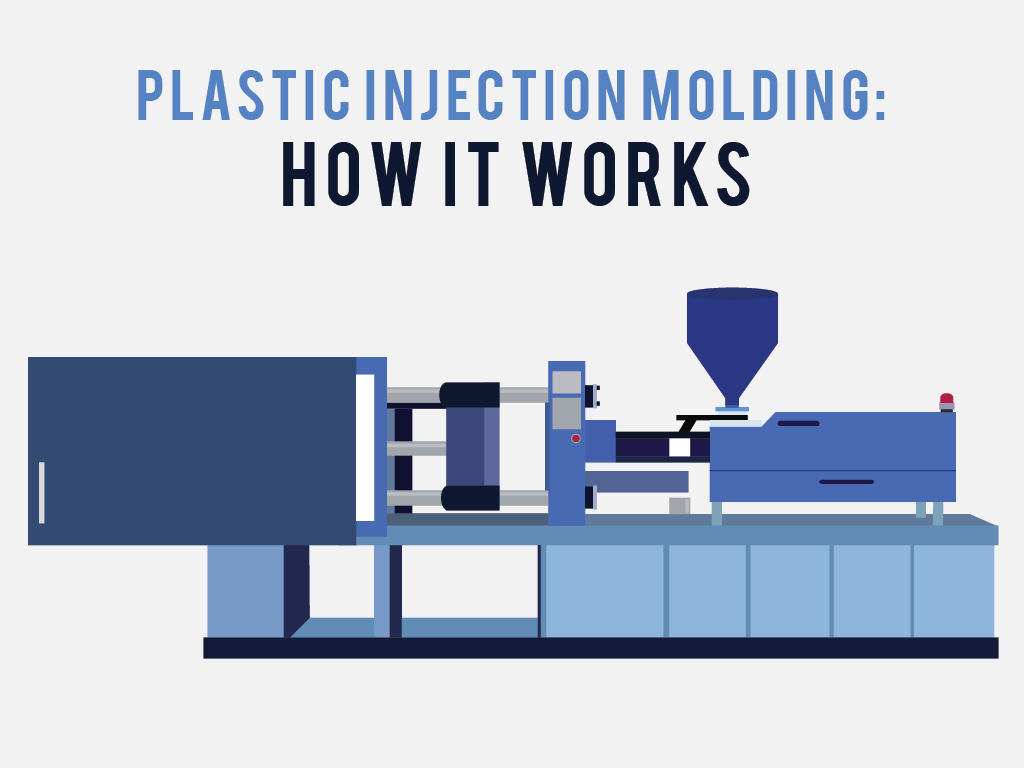

WHAT IS COOLING?

The action of withdrawing energy from the plastic parts inside a mold provide by custom plastic molding company is known as the Cooling stage. This corresponds to the longest phase of the cycle time. Therefore, great attention is important in estimating the ideal cooling time in our processes, in order to obtain the most appropriate costs.

WHEN COOLING STARTS?

The cooling of the plastic begins as soon as the material has contact with the mold, either in the cold channel or in the walls of the cavity. The greatest heat removal occurs during the programmed cooling time, which begins in the vast majority of injectors at the end of the holding time.

However, in some equipment it is possible to program the start of cooling at the beginning of the holding stage.

WHAT IS THE STIMATED COOLING TIME?

The cooling time is easy to estimate based on the wall thickness of the part and the plastic in question? The cooling time is exponential to the thickness of the wall of the piece, the greater the thickness, the required cooling time increases. In our Injection Process Optimization course in custom plastic molding company we provide a useful Excel Calculator for cooling time.

WHAT WILL BE THE THICKNESS OF THE WALL?

- To guarantee an effective cooling time, it is important to design parts with wall thicknesses between 0.65 and 3.8 mm. Each plastic has an ideal thickness range. There are other factors that affect the cooling of the part for example:

- the thermal diffusivity of the plastic

- And the temperature of the mass.

However, the wall thickness is the value that has the greatest effect on the cooling time.

WHAT IS THERMAL DIFFUSIVITY?

According to custom plastic molding company all plastics have a different ability to diffuse the heat from their interior. It is famous as thermal diffusivity and comes by dividing the thermal conductivity of the material with the product of the value of its density and specific heat.

HOW COOLING TIME CAN BE INCREASED?

The higher the temperature of the dough, the amount of heat removes inside the mold increases. Therefore, the cooling time increases. It is important to work with the temperatures indicated by the supplier of the raw material.

The temperature of the metal in the mold is different from the temperature of the water flowing through its cooling ducts.

WHAT IS THE ROLE OF THERMAL DESIGN?

A suitable thermal design by custom plastic molding company has to guarantee a uniform cooling in the piece, and maintain a heat removal at a constant temperature. The pieces are required to cool with the same speed in all their sections, on the contrary, pieces with different dimensions and levels of contraction can be obtained.

WHAT WILL BE THE RESULT OF SMALLER HOSES?

Before making the hose connection, it is essential to identify the coolant inlets and outlets or passages in the mold. Do not connect molds if the cooling circuit is not clearly identified.

Check the diameters of the mold connections and avoid using connectors or hoses with smaller diameters than important. Furthermore, the reduction in diameter results in an increase in pressure drop and low refrigerant flow.

WHY WE HAVE TO AVOID SERIES CONNECTION?

Custom plastic molding company suggests avoiding making series connections by placing jumpers, as this does not create uniform cooling of parts. The parts that are at the beginning of the flow receive a lower temperature than those that are at the end. The series connections generate contraction differences in the pieces, therefore, dimensional variation.

WHAT IS THE IMPORTANCE OF TEMPERATURE?

It is important to examine the temperature of the water entering and leaving the mold. And it determines the temperature drop for each cooling duct. A drop of less than 3 ° C is important to ensure uniform heat removal. When the temperature differential is higher than important, the we should inspect the mold as the cooling ducts may be dirty.

HOW EFFECTIVE COOLING CAN BE ACHIEVED?

The effectiveness of cooling in a mold gets by maintaining turbulent flows in the cooling ducts. According to custom plastic molding company a turbulent cooling flow is more effective at removing heat than a laminar flow. To guarantee the turbulent flow in the cooling ducts of the mold a certain Reynolds number must be generated.

WHAT IS TRANSITION FLOW?

The interval between 2000 and 4000 is considered as transition flow and for values greater than 4000 it is considered as turbulent flow. The Reynolds number is a dimensionless number that relates the physical properties of the fluid, its velocity and the geometry of the pipe through which it flow.

In this article you can learn in detail how to calculate the Reynolds number.

WHAT IS REPRESENTED BY PRESSURE DROP?

The pressure drop represents the opposition of the flow of water entering the mold. Pressure drop is an indicator of flow restriction mainly by:

- dirty pipes

- blocked pipes

- incorrect connections

- use of smaller diameter pipe.