Basic conditions for plastic mold production

As the content of previous articles, we have provided our readers with 4 ways to create Herman miller plastic molded chair. To be able to produce plastic products, molds are needed. Depending on the manufacturing method, different types of molds are used with different structures, names and modes of operation, such as: blow mold, extrusion mold, suction mold, and casting mold.

In this article, we will describe the basic conditions for operating a plastic molding factory, serving the plastic injection molding industry.

Herman miller plastic molded chair

To be able to operate a Herman miller plastic molded chair factory, the following conditions are required.

- Personnel team.

- Mold design team.

This is the team that determines the feasibility of mold production. Each mold manufacturing company must have at least 1 to 3 design staff. To be able to design quality molds.

These designers must have the following abilities:

- Skilled in using 2D, 3D drawing software such as AutoCAD, Creo, Solid works, NX, cimatron, ....

- Having knowledge of mold design such as mold separation, understanding the structure of a set of molds.

- Having experience in mechanical processing at least must know how to operate mechanical processing machines, cnc machining, CNC machining programming in a workshop or mold manufacturing company from 1 year to 3 years.

- Eager to learn to develop themselves, dare to commit to each day improve professional qualifications and design skills.

- And other skills at work.

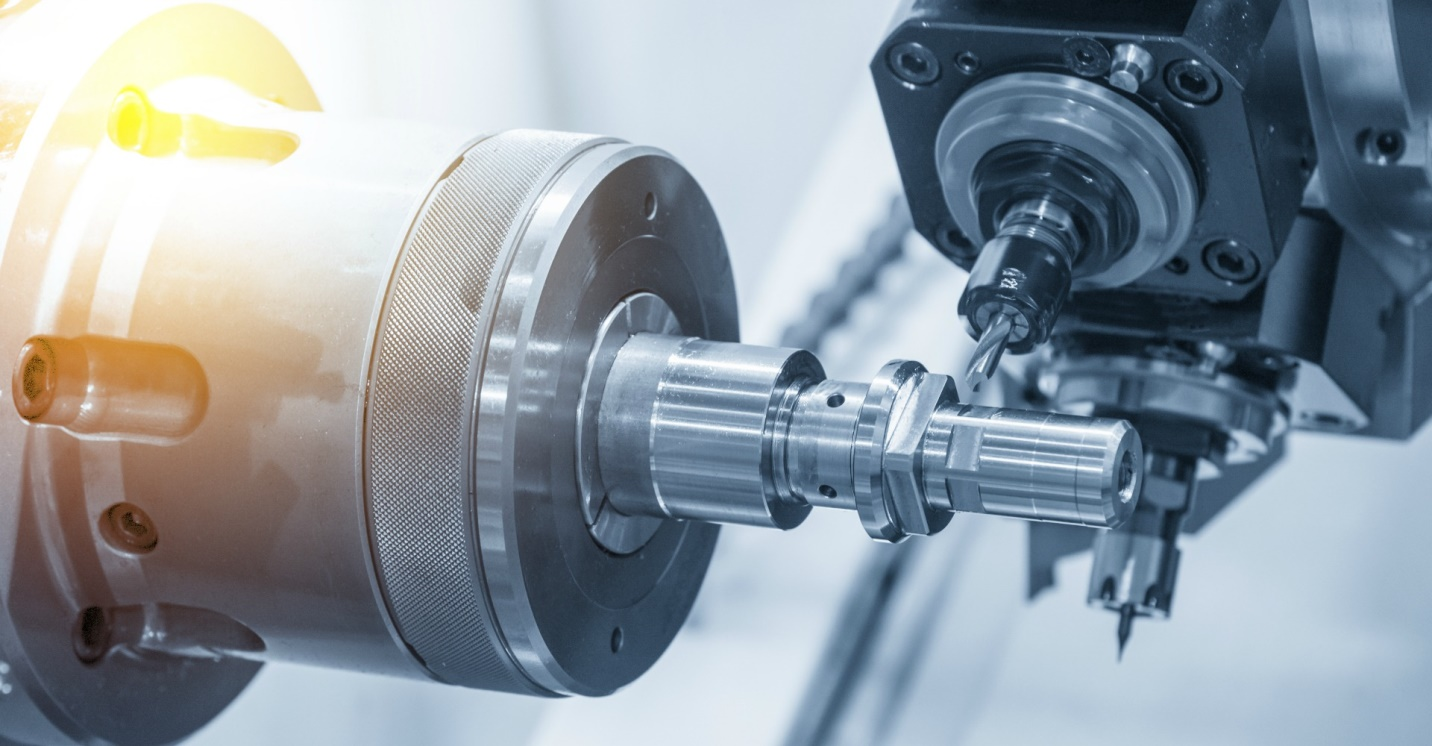

Programming staff and personnel operating mechanical processing machines.

To process a set of Herman miller plastic molded chair. It is a lot of mechanical processing machines are needed. Therefore, it is necessary to have a staff with experience in programming. And the operating mechanical processing machines. Specifically, the staff is as follows:

- Specialist cnc milling programmer, cnc lathe.

- Technician operating cnc milling machine, cnc lathe

- Personnel operating universal processing machines such as vertical milling, horizontal milling, universal turning, flat grinding machine, drilling machine, etc.

- Personnel programming and operating wire cutting machines, spark processing machines.

c. Personnel polishing the Herman miller plastic molded chair

Personnel polishing the mold:

The surface of the mold cavity after machining has a lot of machining marks. And this is due to the shaping properties of the machining. Therefore, to improve the surface quality of the mold cavity. It is necessary to add a polishing process to the surface of the mold cavity. This staff needs to be skilled in the use of polishing machines. Therefore, using different types of polishing tools at each stage: rough, semi-finished, fine and super fine.

– Mold assembly personnel: to assemble mold details into a complete set of molds and at the same time eliminate product errors.

– For small companies, the assembly department also takes care of the polishing staff.

d. Herman miller plastic molded chair Quality control personnel (QC).

This is the team that determines the quality of processing. And this is to ensure that the machined parts meet the dimensions and technical requirements of the design drawings. The better the quality control, the higher the mold quality and vice versa.

- Other support personnel: Purchasing, warehouse keeper, transportation.

- Sales team.

To connect customers to the Herman miller plastic molded chair, it is necessary to have a sales team that is both knowledgeable about plastic mold production and has the skills to find and consult customers. This team receives the customer's requirements and then converts it into a technical problem to discuss with the design team to design a set of molds and then extrude the plastic products that meet the customer's requirements.

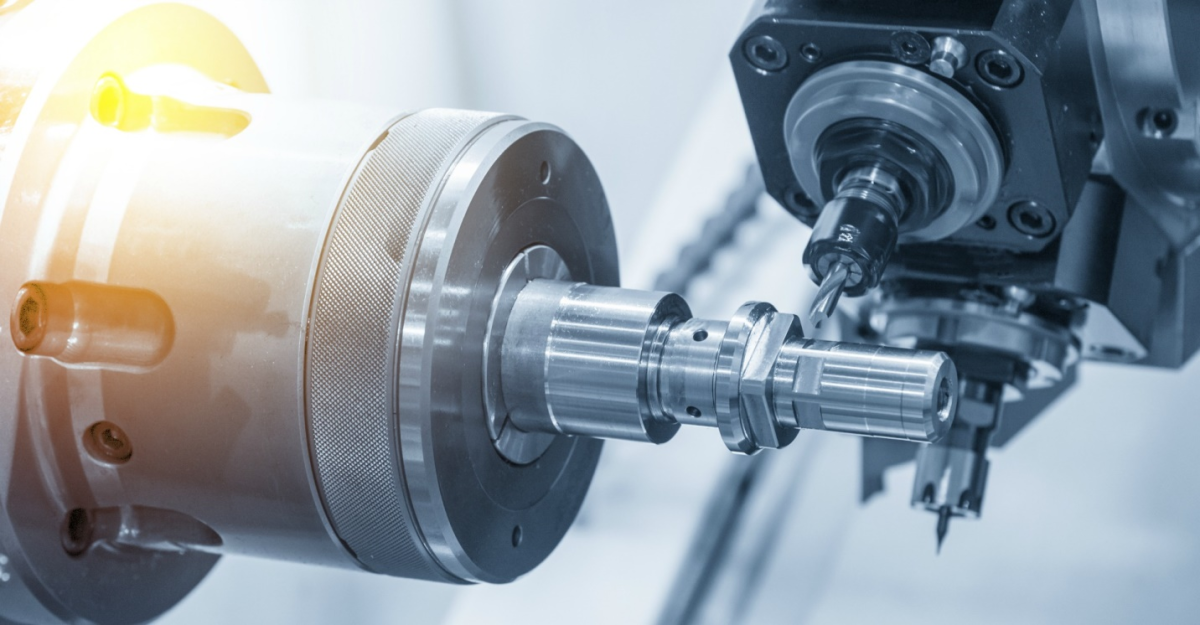

2. Herman miller plastic molded chair Modern and synchronous machinery system.

To produce a quality mold on time, there are many stages, each of which is performed in a certain machine. Therefore, the machinery system is an important factor determining the quality and progress of plastic molding processing. The basic machinery system is as follows:

- Universal processing machines:

- Also, such as vertical milling machines

- horizontal milling machines

- moreover, vertical lathes

- furthermore, drilling machines

- In addition, drilling machines

- flat grinding machines

- Also, insert grinding machines

- stone cutting machines, ...

- Wire cutters.

- Electric spark processing machine.

3. Plastic injection machine for mold testing.

After assembling a complete set of molds. It is necessary to conduct trial production called mold testing. To shorten the mold testing process. It is the mold manufacturing company needs to equip a Herman miller plastic molded chair so that the mold can be tested immediately to evaluate the quality of plastic products and the quality of a set of molds.

Plastic molding machine for mold testing

- Working process system.

The methodical and detailed working process system helps the production system maintain quality, monitor quality, and ensure timely production progress. For plastic injection molding factories, this process system is extremely important.

The basic process system is as follows:

- Mold design process.

- Also, Mold design quality assessment process.

- Moreover, The process of machining a set of molds.

- Furthermore, Detailed machining process.

- In addition, Quality control process

- Also, Assembly process.

- Assembly quality control process.

- Mold testing process.

- Process of handling mold errors.

Necessary to conduct trail production

After assembling a complete set of molds, the next stage is necessary to conduct trial production to evaluate the operability of the mold and evaluate the quality of the product.

To perform this stage, a Herman miller plastic molded chair is required. A professional mold manufacturing company usually has a plastic molding machine to take the initiative in testing samples.

On the other hand, thanks to the plastic molding machine, they can maximize the needs of customers both ordering mold manufacturing and ordering plastic products. That helps customers reduce production waiting time, reduce risks in the plastic molding process, and ensure the confidentiality of the product's production.

Reputable and quality manufacturing company

Above are 5 criteria for choosing a reputable plastic molding company to help customers evaluate and choose an experienced, reputable and quality manufacturing company. Successful entrepreneurs often have a saying "Choice over effort".

When customers have the criteria to choose the right mold making unit, they will avoid worrying about choosing between cost and quality. At the same time, evaluate and choose the right mold manufacturer to give full trust instead of looking for the cheapest mold offering unit.

Only inexperienced mold manufacturers will offer quotations in the direction of market dumping.

Conclusion

Above are the basic conditions for operating a Herman miller plastic molded chair. Because there are many machines and equipment, many stages, many control steps, the time to manufacture a mold is usually from 1 month to 1.5 months. The author of the article is looking forward to receiving your contributions.