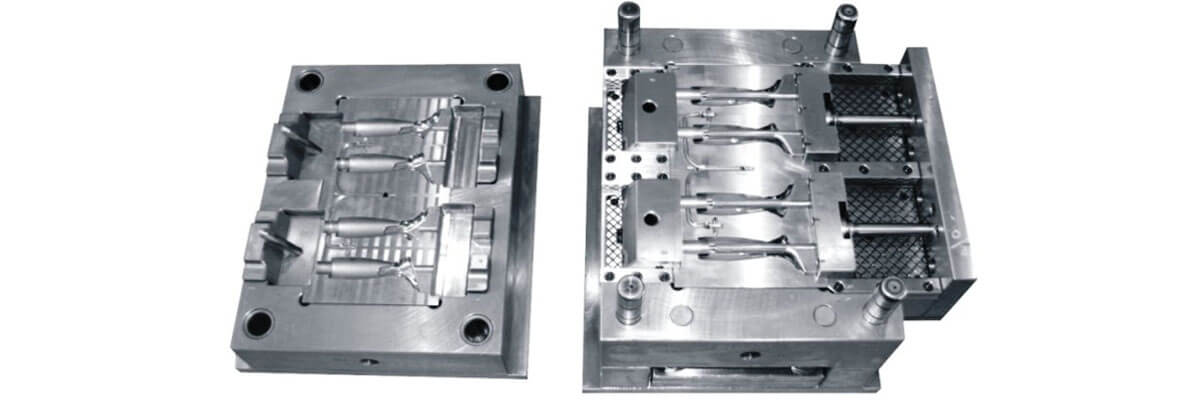

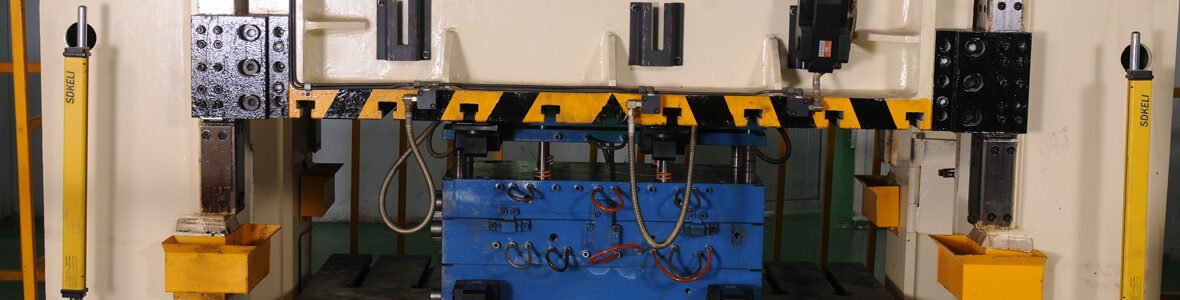

Rapid tooling is a combination of conventional tooling methods and rapid prototyping techniques to create molds faster. With this process, it cuts the time and the cost of producing a mold, ensuring that the product gets into production quicker and reach the market over its competition.

There are many types of rapid prototyping methods available in the market that can help the design team to perfect their product before reaching its customers. But among them, rapid tooling is the frequent choice because of its benefits.

It’s no wonder why because this mold tooling technique is a great way to get the parts inexpensively and quickly. In other words, rapid tooling is the best for making fast and cost-effective molds. Want to know more why rapid tooling is the go-to technique? Read this article to find out.

The Advantages of Rapid Tooling

Before we go to the discussion of why rapid tooling is beneficial for different industries, let’s take a look at the reason why it is essential.

It does not only create a product mold in quickly, but it also helps the designer to take things in the right direction. When the time between the initial design and the prototype is shorter, designers will have the opportunity to analyze it in a real environment. It will give them an idea if they have chosen the right material for the product and if certain parts are viable to serve its purpose.

One of the biggest challenges in production is when the design imperfection is discovered too late, when it is already in the production phase or when the mold is near its completion. Significant faults can have a substantial financial impact on the company. Rapid tooling helps address this issue as the design flaws can be detected earlier.

Lower Cost

The lower the cost of raw materials, the lower the production cost is. And if you are using these molds for your products, you can sell the products without sacrificing its quality and profit. There is a direct domino effect in using rapid tooling; your products can be more saleable to your customers. With cheaper but high-quality products, you can face your competitions and win.

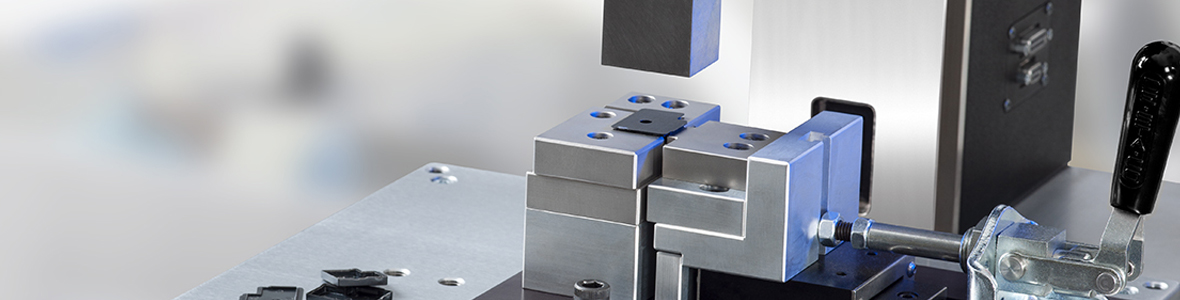

Versatility

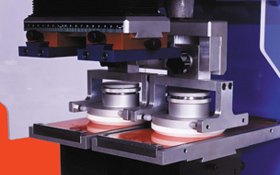

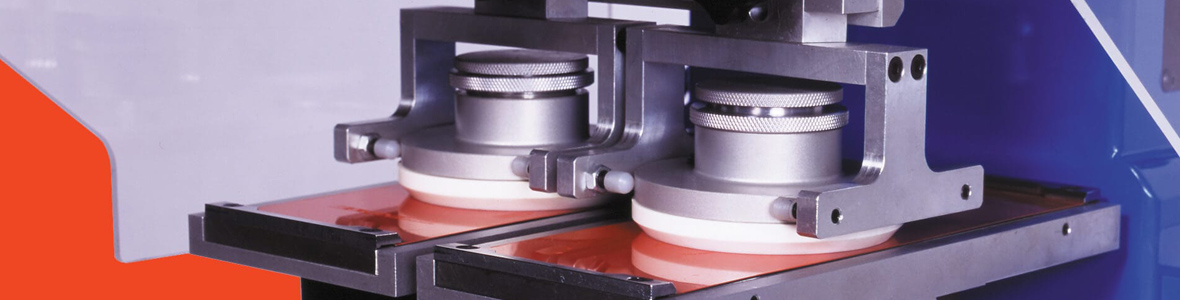

When you have an accurate and precise process, you can produce more parts with a wide range of materials. And the good news is that even if the molds are produced faster through rapid tooling, it can have the same quality as traditional molds but not expensive. It does not affect the strength, color, and surface finishing at all.

Product Consistency

Remember that it uses digital processes and using the same prototype or file can lower the chance of errors and inconsistencies. It speeds up the process even more and produces more products of the same.

You can have more process options with rapid tooling. And that is good news if you want to present more products to your customers. In rapid tooling, you can choose between low volume production for tens to hundreds of parts. Or the intermediate volume processing that can produce hundreds to thousands in quantities. Each has its own set of mold-making processes that enables you to have more options to choose from.

Lastly, It can help your business through bridge production. It refers to a method where you can create a product in small batches and release it to your market before going to full production. It is beneficial to your business because you can introduce the product earlier and gain profit from it before producing the rest.

If there are design flaws, you can correct them before going into mass production. You cannot fix the deficiencies once it is with your customers. Instead, it will create a wrong impression and will be costly for your business.

What’s In Store for Rapid Tooling?

With rapid tooling opening new doors for options in developing parts and products, many companies are investing in technologies that will allow them to create products on demand. The days of conventional tooling are outnumbered with the efficiency and swift delivery of parts.

Because it has reached the domestic level, meaning people can now handle CNC machining tasks even in their garage. The end product has almost the same precision as big manufacturers and workshops.

If you can use these industry-grade materials for your projects, imagine the limitless possibilities it presents to individuals with knowledge and ideas on manufacturing methods. Rapid tooling has made prototyping more accessible.

Companies should not delay their rapid tooling initiatives, or else they will be left out by their competition. Today’s issue is no longer about price and quality, as there are answers to that. What is more pressing is speed, as every industry is focused on delivering results faster. And rapid tooling can help them meet the requirements of the customers to gain a competitive edge.